全站搜索

Search the entire website

Search the entire website

In any crushing operation, the primary jaw crusher gets all the attention. It’s the big, powerful machine at the front of the line doing the heavy lifting. But as an experienced equipment manufacturer, we can tell you a hard truth: your plant’s profitability isn’t decided there. It’s won or lost in the next stage. The downstream crusher selection—your choice of secondary and tertiary crushers—is what truly determines your final product quality, your operational costs, and your ultimate return on investment (ROI).

Making the wrong choice here is like buying a race car and putting cheap tires on it. You’ll never achieve peak performance. This guide is written to prevent that. We will walk you through the five most common and costly mistakes we see operators make when choosing their downstream crushers. More importantly, we will show you how to avoid them, so your crusher selection becomes a source of profit, not a drain on your resources.

Your downstream crushers are responsible for creating the final, sellable product. While the primary crusher just makes big rocks smaller, your secondary crusher and tertiary crusher are the machines that refine that material into the specific sizes and shapes your customers are willing to pay a premium for. An incorrect choice directly impacts your profitability in three ways.

At ZONEDING, we view a crushing plant not as a collection of machines, but as a single, integrated system where every component must work in harmony.

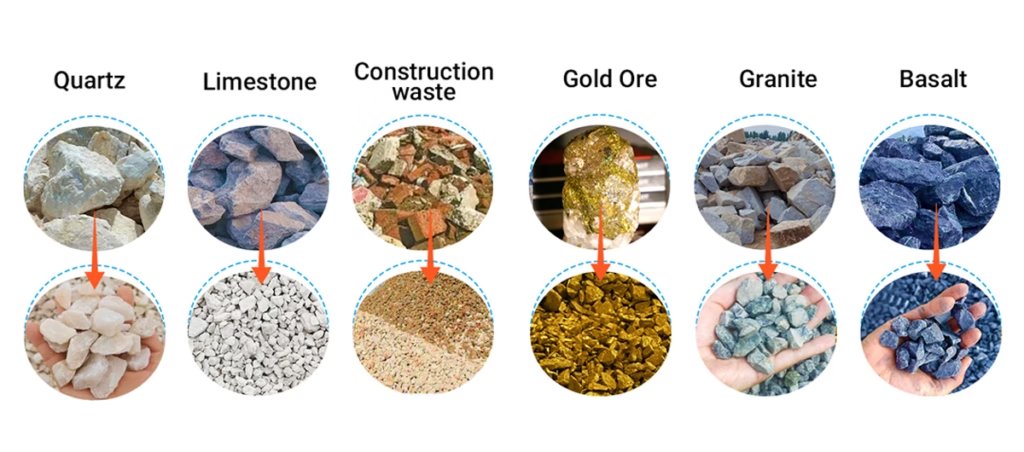

This is the single most expensive mistake you can make. You cannot choose a crusher based on a spec sheet alone. You must know your rock. The most important properties are hardness and abrasiveness (measured by the Silica Content, SiO₂). Using the wrong type of crusher for your rock is a recipe for financial disaster.

Imagine you’re trying to crush a highly abrasive granite or river gravel (high silica). If you choose an impact crusher for this job, you are essentially sandblasting the internal components. The blow bars and impact plates will wear out in a matter of days or even hours. The cost of crusher wear parts will skyrocket, and the constant downtime for maintenance will cripple your production. This is a battle you will never win.

At ZONEDING, the first step in any consultation is a thorough analysis of the customer’s feed material. We know that a profitable operation starts with respecting the rock.

Different crushers are designed for different jobs within the circuit. A crusher that excels in a secondary role may be inefficient as a tertiary finisher. A mismatch here leads to poor performance and an unbalanced plant.

A secondary crusher takes the output from the primary jaw crusher (e.g., 150-300mm) and reduces it to a size manageable for the tertiary stage (e.g., 40-60mm). This stage is all about efficient size reduction. A Standard Head cone crusher or a primary impact crusher is often used here.

A tertiary crusher takes this smaller feed and refines it into the final product sizes (e.g., 0-20mm). This stage is about precision and shape. A Short Head cone crusher or a Vertical Shaft Impact (VSI) crusher is ideal. Using a crusher designed for coarse secondary work in a fine tertiary role will result in poor product shape and a high percentage of undesirable dust.

ZONEDING manufactures a full range of crushers, each optimized for its specific role in the crushing circuit.

In today’s market, shape sells. For concrete and asphalt applications, customers demand a cubical, well-shaped aggregate. Flaky and elongated particles are weak, create voids, and require more expensive cement or bitumen to compensate. If your crusher produces poorly shaped aggregate, your product will be considered low-grade, and you’ll be forced to sell it at a lower price.

This is the classic cone crusher vs impact crusher trade-off. Cone crushers, which use compression, can sometimes produce more flaky particles, especially with certain rock types. Impact crushers, which shatter rock through high-velocity collision, are champions at improving aggregate cubicity and shape. If your market demands premium cubical aggregate, your downstream crusher selection must include an impact crusher (like a VSI) in the final stage, assuming your rock isn’t overly abrasive.

Focusing only on the initial purchase price of a crusher is a short-sighted strategy that almost always leads to higher costs in the long run. A cheaper machine from an unproven supplier may save you money today, but it will cost you dearly in downtime, frequent parts replacement, and lower efficiency.

The cost of crusher wear parts is a major factor. A well-engineered crusher from a reputable manufacturer like ZONEDING uses superior manganese steel alloys and optimized chamber designs that extend the life of liners and blow bars, significantly reducing your cost per ton. Energy consumption is another huge expense. A more efficient crusher design can save you thousands of dollars in electricity costs over its lifetime. A smart crusher selection is based on the Total Cost of Ownership (TCO), not just the initial price tag.

A crushing plant is a system. The output of one machine is the input for the next. If your secondary crusher cannot keep up with the primary, or if the tertiary crusher is starved of material, you have a bottleneck. An unbalanced circuit is an inefficient circuit.

For example, if you pair a large primary jaw crusher with an undersized secondary cone crusher, you’ll have a mountain of coarse material piling up. The jaw crusher will have to sit idle, wasting capacity. Conversely, if your secondary crusher is too large for your tertiary crusher, the tertiary machine becomes the bottleneck. Proper downstream crusher selection involves carefully matching the capacity and reduction ratios of each machine to ensure a smooth, continuous flow of material. This is why ZONEDING’s engineers always design the entire circuit, not just sell individual machines.

Because of its crushing principle: compression. A cone crusher works by squeezing rock between a fixed outer liner (bowl liner) and a moving inner liner (mantle). It’s like a powerful, industrial-scale mortar and pestle.

This compression action is far more suitable for a cone crusher for hard rock application (like granite, basalt, or quartzite) than the violent impact of an impact crusher. Since the rock is being ground against wear-resistant manganese steel liners rather than smashed at high speed, the wear rate is much, much lower. This dramatically reduces the cost of crusher wear parts and minimizes downtime. If your primary goal is the cost-effective size reduction of hard, abrasive materials, a cone crusher is almost always the correct answer for your secondary and tertiary stages.

When your final product specification demands a premium cubical shape. An impact crusher works by using a high-speed rotor to throw rocks against stationary impact plates or, in the case of a Vertical Shaft Impactor (VSI), against a bed of other rocks.

This high-velocity collision causes the rock to shatter along its natural fracture lines. This process naturally produces particles that are more uniform and cubical in shape. For materials like limestone or in applications where shape is more important than wear cost (like the final stage of aggregate production), an impact crusher is essential. An VSI Crusher, in particular, is the ultimate “shape-making” machine and is the key to improving aggregate cubicity and shape to meet the most stringent specifications.

To make a truly informed crusher selection, you need to look beyond the invoice price. The Total Cost of Ownership (TCO) gives you the true cost of a machine over its entire life. At ZONEDING, we help our clients calculate this so they can make a data-driven decision.

| Cost Component | Description | How It Impacts Your Bottom Line |

|---|---|---|

| Purchase Price | The initial investment in the machine. | The most visible cost, but often only 20-30% of the TCO. |

| Energy Costs | The electricity required to run the crusher motor. | A 10% more efficient motor can save tens of thousands of dollars over the crusher’s life. |

| Wear Part Costs | The cost of replacing liners, mantles, blow bars, etc. | This can be the largest single operating expense. High-quality parts last longer. |

| Maintenance Labor | The man-hours required for routine service and repairs. | Machines designed for easy access (e.g., with hydraulic opening) reduce this cost. |

| Downtime Cost | The lost revenue when the crusher is not running. | This is the hidden killer. A reliable machine with good parts availability minimizes this. |

Your downstream crusher selection is one of the most significant financial decisions you will make for your plant. The key is to shift your focus from the purchase price to the Total Cost of Ownership and from raw power to final product value.

Avoid the common mistakes: know your rock, match the crusher to its role, prioritize product shape, calculate the TCO, and design a balanced circuit. By understanding the fundamental cone crusher vs impact crusher trade-offs and partnering with an expert manufacturer, you can ensure your choice leads to higher profits, lower costs, and a sustainable competitive advantage.

Starting a limestone processing plant is a big project, but it can be very profitable. The process involves taking large rocks from a quarry and turning them into valuable products like construction aggregate or lime. You need a solid plan, the r...

View detailsYour cone crusher is the heart of your operation. And its heart is made of steel. Specifically, the Cone Crusher Liner set is where all the work happens. Choosing the right liners, and knowing when and how to change them, is not just maintenance....

View detailsA modern, intelligently designed sand washing plant is the definitive solution for improving the value of your sand. Many perceive the sand washing process as simply rinsing sand with water, but this is a vast oversimplification. A truly effectiv...

View detailsIn your mining or aggregate operation, managing water is not just an operational task—it is a core driver of your profitability. Excess water in your product inflates shipping costs, reduces material quality, and creates significant safety risks....

View details