全站搜索

Search the entire website

Search the entire website

Iron ores are rocks and minerals from which metallic iron can be economically extracted. Iron ore are the raw materials to produce pig iron that is the main source of making steel. For iron ore beneficiation, there are multiple stages including crushing, grinding, classification and separation. Firstly, by crushers, raw iron ores can be crushed into little particles. Next, those particles would be sent into grinding mills to be ground into fine powders. Finally, through specific beneficiation methods such as gravity separation and flotation, iron concentrates can be got.

ZONEDING MACHINE focuses on manufacturing mineral processing equipment. ZONEDING MACHINE produces machines for crushing rocks, such as iron ore. Iron ore processing is very important, and it differs from crushing stone for construction purposes. Processing iron ore is not just about crushing it into smaller pieces; more importantly, it’s about crushing it to prepare for the next step: extracting valuable iron. This process is called beneficiation. The way iron ore is crushed directly affects the efficiency of iron extraction. ZONEDING MACHINE will explain how to effectively crush iron ore, which helps you extract more iron and increase profitability.

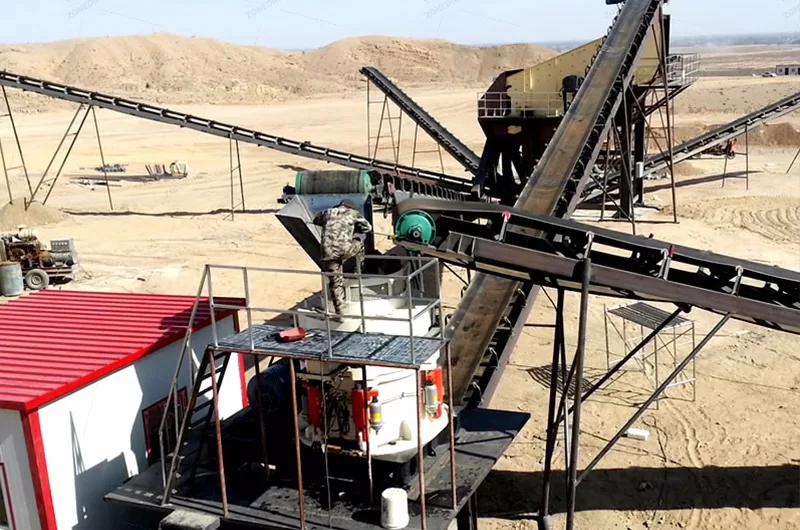

Here are very common iron ore crushing plants for reference. They have been proven by practice. And they have the advantages as follows:

Iron ore is not just one type of rock. It has different minerals inside. It has iron minerals and waste rock, called gangue or barren rock. The iron mineral can be hard or softer. The waste rock can also be hard and abrasive. This makes crushing iron ore tricky. The exact minerals in your iron ore change how it breaks. It changes how much it wears out your machines.

Some iron ore is hard like granite. Some is softer. Some types are very abrasive. This means they rub away the metal parts in crushers and screens very fast. The mix of hard iron minerals and hard, abrasive waste rock puts special stress on crushing machines. You need machines built strong. You need parts that can handle the rubbing and the impact. Also, iron ore is heavy. It is dense. This high weight can put more load on conveyors and screens. This density can also cause material to pack together. This can make it difficult to handle the material smoothly.

Crushing gravel for roads is about making rock a certain size and shape. Crushing iron ore is different. You crush iron ore to separate the iron minerals from the waste rock. This is called liberation. You need to break the rock until the valuable iron pieces are free from the waste pieces. How fine you need to crush depends on the ore.

If you do not crush small enough, the iron is still stuck to the waste rock. Then you cannot get all the iron out in the cleaning process. If you crush too much, you make too much fine dust. This fine dust is hard to handle in the cleaning process. It can lower how much iron you get. It also adds costs for dust control. So, the goal is to crush just enough. You need to liberate the iron minerals. You need to make the right size range for the cleaning machines that come after the crushing plant. The minerals inside your specific iron ore tell you how fine you need to crush. This is a key difference from just making aggregate.

You need tough machines for crushing iron ore. The machines must be strong enough to break the hard parts. They must also be built to handle the abrasive parts. For the first step, taking big rocks from the mine, you need a primary crusher. A is the standard choice. It is very robust. It uses powerful plates to squeeze big rocks. It can take large lumps of iron ore. It breaks them into smaller pieces.

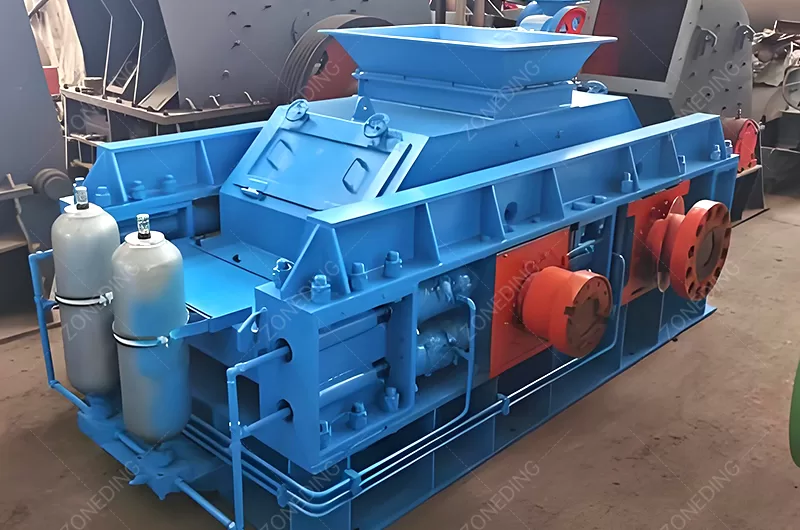

After the jaw crusher, you need to break the rock even smaller. Cone Crushers are often used for the second and third crushing stages. They squeeze rock between a moving cone and a bowl liner. This works well for hard, abrasive materials. Cone crushers also help control the final size of the rock. For some types of iron ore, or to make very fine material before cleaning, you might use other crushers like a Roll Crusher or a VSI Sand Making Machine. But the Jaw Crusher and Cone Crusher combination is very common and effective for many iron ore types.

The Jaw Crusher is the first machine to see the raw iron ore. It must be able to take whatever size comes from the mine. It needs to handle hard, large pieces. It breaks them into pieces small enough for the next machine. Jaw crushers are built very heavily for this task.

The Cone Crusher is used after the jaw crusher. It breaks the rock down further. Cone crushers are good for iron ore because they can crush hard rock efficiently. You can adjust the gap in a cone crusher to change the size of the crushed rock. This is important for getting the right size for cleaning. A typical iron ore crushing plant might have one jaw crusher and then one or two cone crushers. This multi-stage crushing process breaks the rock down step by step. This uses energy more efficiently and helps you control the final product size.

| Crusher Type | Best Use Case | Key Benefit for Iron Ore |

|---|---|---|

| Jaw Crusher | Primary Crushing | Handles large feed, Robust |

| Cone Crusher | Secondary/Tertiary | Efficient for hard rock, Size control |

| Roll Crusher | Sometimes Fine Crushing | Can produce specific fine sizes |

| VSI Sand Making Machine | Sometimes Shaping/Fine | Can improve particle shape (use with care on abrasive ore) |

Yes, wear is a big cost in crushing iron ore. The abrasive minerals in the ore grind away the metal parts inside the machines. These are wear parts like jaw plates, cone liners, and screen media. When these parts wear out fast, you have to stop the plant to change them. This costs money for new parts. It also costs money because you are not producing iron ore during the stop. You need smart ways to make wear parts last as long as possible.

Choosing the right material for wear parts is a secret weapon. For hard and abrasive iron ore, wear parts are often made from special steel alloys, like high manganese steel or chrome alloys. The exact alloy depends on how abrasive your ore is. A good supplier will recommend the best material for your specific ore. How you feed the crusher matters too. Sending a steady stream of rock into the crusher helps the wear parts wear more evenly. Overloading or underloading can cause parts to wear faster in certain spots. Proper adjustment of the crusher settings also affects wear. Running the machine correctly helps make the wear parts last longer.

It is not just about buying expensive parts. It is about managing them smartly.

A smart iron ore crushing plant is designed for high production and efficiency. It takes the raw ore from the mine and prepares it perfectly for the cleaning process. The design is not just about crushing. It is also about moving the material smoothly. It is about screening the material accurately. The process must handle the heavy nature of iron ore. It must also minimize fines (dust) production.

A typical smart process starts with a heavy-duty primary feeder. This feeder controls the flow of large rocks into the Jaw Crusher. After the jaw crusher, the material goes to a screen. This is a Vibrating Screen. The screen takes out the pieces that are already small enough. This stops small pieces from going through the next crusher. This saves energy and reduces wear on the secondary crusher (Cone Crusher). The larger pieces go to the secondary crusher. You might have another screen and a tertiary crusher (Cone Crusher) to get the final desired size distribution for cleaning. Good conveyors connect all these machines. The conveyors must be strong to carry the heavy iron ore. Using screens at each stage is key. It makes sure only oversized material is crushed again. This makes the process efficient and helps control the final product size.

Here is what a good process flow looks like:

Iron ore is dense. This means a certain volume of iron ore is heavier than the same volume of other rocks like limestone. This density can cause problems in the crushing plant. The heavy material puts more stress on conveyors. It can also pack together in crushers or chutes. This packing can lead to blockages. A blockage stops the flow of material. This stops the whole plant. You lose production time. Blockages can be dangerous. You need to design and operate the plant to prevent them.

Preventing blockages starts with the design of the equipment and the plant layout. Crusher cavities should be designed to allow material to flow freely. Chutes that move material from one machine to another should be steep enough. They should be designed to prevent material build-up. Good feeders (Vibration Feeder) are important. They control the rate at which material enters the crusher. This stops the crusher from being overloaded. Regular cleaning helps too. Removing built-up fine material or sticky ore keeps pathways clear. Monitoring systems can help detect potential blockages early. You can then stop the flow before a full blockage happens.

The size of the crushed iron ore is very important. It must be the right size for the mineral cleaning process that comes after crushing. This is called beneficiation. Iron ore is cleaned using methods like magnetic separation, gravity separation, or flotation. Each method works best with a certain size range of material. If the crushed ore is too big, the iron minerals are still locked inside the waste rock. The cleaning machines cannot separate them. You lose valuable iron.

If the crushed ore is too small, especially making too much fine dust, it causes problems. Fine dust is hard to handle in water-based cleaning processes. It can make the water dirty. It can lower the efficiency of the cleaning machines. Some iron can be lost with the fine waste. The crushing plant’s goal is to produce material that is just the right size. You need to break the rock enough to free the iron minerals. But you must avoid making too much fine dust. You achieve this by using the right sequence of crushers (Jaw Crusher, Cone Crusher) and screens (Vibrating Screen). You need to adjust the crushers and screens precisely. This makes sure the final product from the crushing plant has the perfect size distribution for your specific iron ore cleaning process.

Running an iron ore crushing plant costs money in several ways. The purchase price of the equipment is only one part. You have ongoing costs that happen every day or month. Power use is a big cost because breaking hard, dense iron ore takes a lot of electricity or fuel. Wear parts cost a lot because iron ore is abrasive. You pay people to run and maintain the plant. Maintenance costs include fixing machines and planned checks. If the plant stops working, you lose money because you are not producing ore.

To make a profit, you need to look at the total cost to produce one ton of crushed iron ore. This includes all your operating costs. To lower this cost per ton, you need to be efficient. Lowering wear costs means buying good parts and running machines correctly. Reducing energy costs means using efficient machines and optimizing the process flow. Preventing breakdowns saves money on repairs and avoids lost production. Good planning and operation are key. You also have costs for things like dust control systems, water use, and environmental permits. Sometimes site preparation and building infrastructure are significant upfront costs beyond the machines themselves. When you think about buying equipment, always consider these long-term operating costs.

Investing in an iron ore crushing plant is more than just buying crushers. You need to consider the total investment.

Mobile crushing plants are built on wheels or tracks. They can move. For iron ore projects, mobile crushers can offer some advantages. If your iron ore deposit is spread out, or if you move your mining area often, a mobile crusher can move with the mining operation. This reduces the distance you have to haul the raw ore from the mine to the crusher. Hauling is expensive. Cutting hauling distance saves money.

Mobile crushers can be primary (Mobile Jaw Crusher) or secondary/tertiary (Mobile Cone Crusher). They are good for projects that need to start up quickly or are temporary. They can be faster to set up compared to building a large fixed plant. Some modern plants use a modular design. This is like building the plant from pre-made blocks or modules. These modules can be transported and put together quickly. This is similar to the flexibility of mobile plants but can sometimes achieve higher total capacity. Mobile plants might cost more to buy per ton of capacity than fixed plants. They often use diesel generators, which can have higher fuel costs than grid electricity. So, you need to weigh the benefits of flexibility and reduced hauling against the potential higher costs per ton processed.

Think about your project needs when choosing.

Choosing the right supplier for your iron ore crushing plant is critical for success. Iron ore has unique properties. It is heavy, often hard, and can be very abrasive. You need a supplier who truly understands these challenges. They should have experience designing and building plants that process iron ore successfully. An experienced supplier knows which crusher types, sizes, and configurations work best for different kinds of iron ore. They know how to design the process flow to maximize liberation and minimize fines for your specific ore and cleaning method. They can recommend the best wear part materials to save you money.

Look for a supplier with a long history in mineral processing. Ask if they have worked on iron ore projects before. They should have a team of qualified engineers. These engineers should ask for samples of your iron ore. They need to test it and analyze its properties. Then they should design a solution tailored to your specific ore and your cleaning plant’s needs. A good supplier offers more than just machines. They provide full services: from plant design and manufacturing to helping with installation, training your staff, and providing ongoing technical support and spare parts. Iron ore processing is complex. You need a partner with proven knowledge and reliable equipment. ZONEDING has many years of experience. We have designed and supplied mineral processing plants, including crushing plants, for various ores in over 120 countries. Our engineers specialize in understanding different ore types. We can help you design a plant that efficiently processes your iron ore.

Q 1: Why is crushing important before iron ore cleaning?

A: Crushing breaks the iron ore to free the valuable iron minerals from waste rock, which makes the cleaning process like magnetic separation possible and more effective.

Q 2: How do I prevent excessive wear in my iron ore crusher?

A: Use high-quality wear parts made from materials suitable for abrasive ore, operate your crushers and feeders (Vibration Feeder) correctly, and perform regular maintenance.

Q 3: What is the best crusher type for primary iron ore crushing?

A: A robust, heavy-duty Jaw Crusher is typically the best choice for the primary stage of crushing large iron ore rock from the mine.

Q 4: Can mobile crushers be used for iron ore projects?

A: Yes, mobile crushers (Mobile Jaw Crusher) can be used. They offer flexibility and reduce raw material hauling costs, especially for certain types of deposits or projects needing fast setup.

Q 5: How does iron ore density affect crushing?

A: High density means the material is heavy. This puts stress on conveyors and can cause material to pack or bridge inside crushers and chutes, potentially leading to blockages.