The crushing process is the heart of turning large, unusable rock into valuable, specific-sized products like sand and gravel. The goal of any rock crushing plant is to reduce the size of raw material through a series of stages to produce aggregates that meet specific quality and size requirements for construction, mining, or industrial use. It’s a foundational step for much of the modern world’s infrastructure.

Table of Contents

What is the Rock Crushing Process?

The rock crushing process is a multi-stage mechanical procedure designed to reduce the size of large rocks into smaller, more manageable pieces. It involves feeding raw stone into different types of crushing machines that use force to break the material apart. This isn’t a random smashing; it’s a controlled process. Each stage of crushing and screening is carefully designed to achieve a specific size reduction and shape, ensuring the final product meets the strict standards required for applications like concrete or asphalt production.

What are Types of Crushing Method?

Understanding the method of crushing helps you choose the right machine. All crushers use force, but they apply it in different ways.

- Compression: This is a squeezing force. It’s like placing a nut in a nutcracker. Jaw crushers and cone crushers are the primary examples. This method is great for breaking down hard, abrasive rock in the initial stages.

- Impact: This involves a high-speed collision, like hitting a rock with a sledgehammer. Impact crushers use this principle, throwing rocks against solid surfaces or other rocks. This method excels at creating a more cubical, high-quality product shape.

- Attrition: This is the rubbing action of particles against each other. It’s a key part of the process inside VSI (Vertical Shaft Impact) crushers and helps to round off sharp edges, improving the final product’s shape.

- Shear: This is a slicing or tearing action, often used in specialized crushers for softer materials, but less common in hard rock applications.

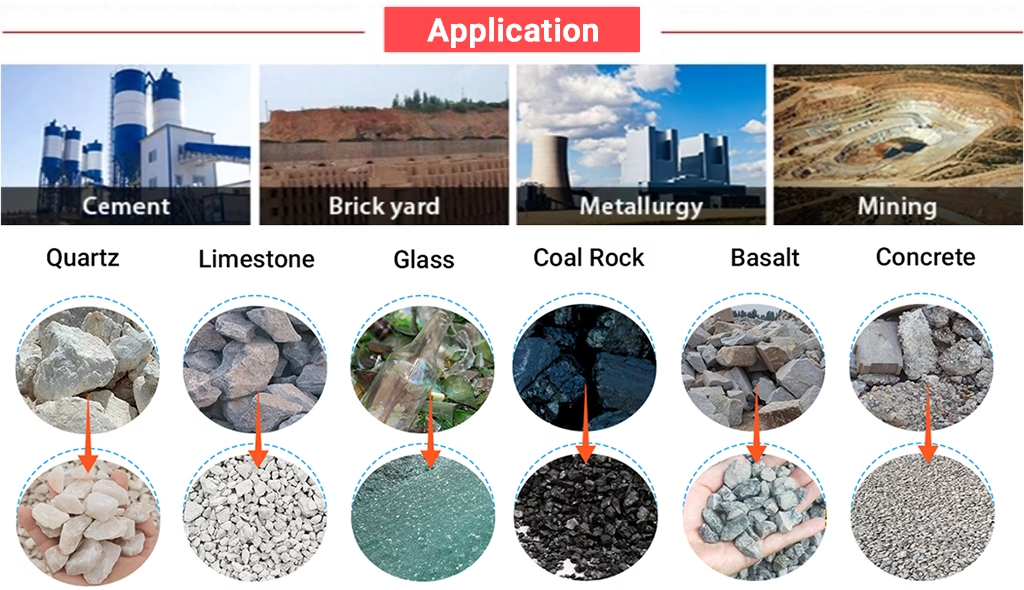

Which Industry Need a Rock Crushing Plant?

A surprising number of industries rely on the crushing process. If you see a road, a building, or a bridge, you are looking at the end products of a crushing plant.

- Quarrying & Aggregate Production: This is the most common. Quarries produce sand, gravel, and crushed stone for concrete, asphalt, and road base.

- Mining: In crushing process in mining, crushers are used to break down large ore-bearing rocks to a size that can be processed to extract valuable minerals like gold, copper, or iron.

- Construction & Demolition Recycling: Old concrete, bricks, and asphalt from demolished structures are crushed and repurposed as recycled aggregate for new construction projects.

- Cement Industry: Limestone and other raw materials are crushed into a fine powder as the first step in manufacturing cement.

Which Type Materials can be Crushed?

Crushing equipment is incredibly robust and can handle a wide variety of materials, though the machine choice depends on the material’s properties.

- Hard Igneous Rock: Granite, Basalt, Gabbro

- Sedimentary Rock: Limestone, Sandstone, Dolomite

- Metamorphic Rock: Quartzite, Marble

- Ores: Iron Ore, Copper Ore, Gold Ore

- Recycled Materials: Concrete, Asphalt, Construction Debris

- Industrial Minerals: Bauxite, Phosphate Rock

What Materials can use Jaw crushers?

Jaw crushers are designed for the toughest jobs. They can handle a wide variety of hard and abrasive materials.

- Hard Rock: Granite, basalt, gabbro, quartzite.

- River Stone: Hard, rounded, and very abrasive.

- Ores: Iron ore, copper ore, gold ore.

- Recycled Materials: Demolished concrete, asphalt chunks.

How the Raw Material Affect the Crushing Process?

The raw material is the single most important factor in designing a crushing plant. You must understand its properties before you buy a single piece of equipment.

- Hardness & Abrasiveness: Hard, abrasive materials like granite or quartzite will cause wear parts (like jaw plates and cone liners) to wear down much faster. This increases your operational costs. For these materials, you need crushers built with high-manganese steel and robust designs.

- Moisture Content: Wet, sticky material can clog up crushers and screens, causing blockages and significant downtime. If your material has high moisture content, you may need specialized feeders or scalping screens to remove the wet fines before they enter the primary crusher.

- Size and Shape: The maximum size of the rock you need to feed (the “feed size”) determines the opening size of your primary crusher. A plant designed for river stone won’t be able to handle large blasted rock from a quarry.

Is It Profitable for Crushing Plant?

Yes, a crushing plant can be very profitable, but it is a business with significant upfront investment and ongoing operational costs. Profitability depends on several key factors:

- Market Demand: Is there a local need for aggregates? Proximity to construction projects is key, as transportation is a major cost.

- Aggregate Price: The selling price per ton of your final products.

- Initial Investment: The cost of the land, permits, and all the crushing and screening equipment.

- Operating Costs: This is crucial. It includes labor, fuel/electricity, wear parts, and maintenance. Efficiently managing these costs is the difference between profit and loss.

- Quality of Final Product: Producing well-graded, cubical aggregate that meets specifications will command a higher price and attract more customers.

What are Advantages of Multi-Stage Crushing Process?

You might wonder why we don’t just use one giant crusher. A multi-stage crushing process is far more efficient and effective for several reasons:

- Higher Efficiency: Each type of crusher is designed to work best within a specific size reduction range. A primary crusher is good at breaking huge rocks into medium ones. A secondary crusher is good at turning medium rocks into small ones. Using them in stages puts less strain on each machine.

- Better Product Quality: Multiple stages, especially when using impact crushers in the final stages, allow you to control the shape (cubicity) of the final aggregate. A single-stage process often produces flaky, elongated particles which are weak in concrete.

- Greater Flexibility: A multi-stage plant allows you to produce multiple products of different sizes at the same time. You can separate and sell different sizes of gravel and sand from the same raw feed.

- Lower Wear Costs: By gradually reducing the rock size, you minimize the stress on any single machine, extending the life of your expensive wear parts.

What are Stages of Crushing Process?

A typical crushing plant layout design involves three or four key stages. Think of it as a production line for rock.

What Happens During the Primary Crushing Stage?

This is the first and most brutal stage. The goal is to break down the largest “run-of-mine” rock into a more manageable size. The workhorse of this stage is usually a Jaw Crusher. It uses compression to squeeze the rock. The primary crusher must be robust enough to handle the largest and hardest material from your quarry, and its output size is typically around 150-300mm (6-12 inches).

What is the Role of Secondary and Tertiary Crushing?

After primary crushing, the rock moves to the secondary stage. Here, a Cone Crusher or an Impact Crusher takes the medium-sized rock and reduces it further. The tertiary crusher is the final stage of crushing, where the goal is to produce the final product sizes, like fine aggregates for concrete or asphalt. Cone crushers are excellent for hard rock, while impact crushers are often preferred in the tertiary stage for their ability to produce highly cubical, well-shaped particles. This is where you really start to create the valuable, specific products you will sell.

Why Screening is so Important?

Crushing and screening go hand in hand. A crusher breaks the rock, but a screen separates it. Vibrating screens are large sieves that sort the crushed material by size. Screening is critical for two reasons:

- Efficiency: It removes correctly sized material from the circuit, so you don’t waste energy re-crushing it.

- Product Quality: It ensures that your final products (e.g., 10mm gravel, 20mm gravel, manufactured sand) are precisely sized and separated, meeting customer specifications. Without effective screening, you just have a pile of mixed rock, not a sellable product.

How Do You Choose the Right Crusher for Each Stage?

Choosing the right crusher is about matching the machine to the job.

- Primary Stage: You need a machine with a large feed opening that can handle hard rock. The Jaw Crusher is the industry standard.

- Secondary Stage: For hard, abrasive rock, a standard Cone Crusher is the best choice. For softer materials like limestone, a primary impact crusher can be used.

- Tertiary Stage: To produce sand or fine, cubical aggregate, a high-speed Cone Crusher or a Vertical Shaft Impact (VSI) Crusher is ideal.

What Other Equipment is Essential for a Crushing Line?

A crushing plant is more than just crushers.

- Vibrating Feeder: Controls the flow of material from the hopper into the primary crusher, ensuring a steady, consistent feed.

- Conveyor Belts: The arteries of the plant, transporting material between the different stages.

- Hoppers & Bins: Used for temporary storage of raw feed and final products.

- Dust Suppression System: Essential for environmental compliance and a safe working environment.

How to Choose Right Crusher Plant for My Project?

Choosing the right plant is a major decision. Here are the questions I ask my clients at ZONEDING:

- What is your raw material? (Hardness, size, moisture)

- What final products do you want to make? (Specific sizes and quantities)

- What capacity do you need in tons per hour (TPH)?

- What is your site like? Do you need a fixed, stationary plant, or a mobile crushing plant that can be moved?

- What is your budget? Consider both the initial purchase and long-term operating costs.

Answering these questions will guide you to the right combination of crushers, screens, and support equipment for a successful operation.

Common Challenges on Rock Crushing Process

Running a crushing plant is not without its challenges. Being prepared for them is key.

- Wear Part Management: All crushers have parts that are designed to wear out. Managing your inventory of spare jaw plates, cone liners, and impact bars is crucial to minimize downtime.

- Blockages: Wet, sticky material or oversized rocks can cause blockages in the crusher or transfer chutes. Proper feed preparation is the best prevention.

- Dust and Noise Control: Meeting environmental regulations for dust and noise is a major consideration. This requires investment in water spray systems, baghouses, and equipment enclosures.

- Inconsistent Feed: The quality of your final product is directly related to the consistency of the material you feed into the plant.

ZONEDING – YOUR RELIABLE SUPPLIER

At ZONEDING, we’ve been manufacturing mining crushing equipment since 1990. We understand that a crushing plant is a long-term investment that needs to be productive and reliable. We offer a comprehensive line of equipment, providing complete, one-stop solutions for crushing and screening plants. Because we are a manufacturer selling directly to you, we can offer a more competitive price without compromising on quality. Our equipment uses high-durable steel for wear parts and incorporates world-class components like Siemens PLCs and Schneider inverters. With over 30 years of experience and equipment operating in over 120 countries, our team of engineers has the expertise to design a plant that is perfectly optimized for your specific material and business goals.

FAQ

- What are the Key Factors that Determine Production Capacity (TPH)?

- Capacity is determined by the “bottleneck” in your plant. The main factors are the primary crusher’s size and setting, the width of the conveyor belts, and the surface area of your screens. The hardness of the rock also plays a big role; you can process more tons of soft limestone per hour than hard granite with the same machine.

- How Can You Minimize Operational Costs and Downtime? How to Maintain My Crusher Machine?

- Proactive maintenance is everything. This means daily inspections, following the lubrication schedule strictly, and monitoring the wear on your parts. Train your operators to listen for unusual noises and to feed the plant consistently. Keeping a stock of critical spare parts is the best insurance against long, costly shutdowns.

- How Much Money Should I Prepare for My Rock Business?

- The investment for a rock crushing business varies widely. A small, portable plant might start around $150,000 to $300,000. A complete, medium-capacity stationary plant (200-300 TPH) could range from $800,000 to over $2 million. This cost includes crushers, screens, conveyors, and electrical controls. You also need to budget for land, permits, site preparation, and initial operating capital.