全站搜索

Search the entire website

Search the entire website

Gypsum is a foundational material in the modern construction industry. You can find it everywhere, from the walls of your home to the plaster in art studios. As a manufacturer of mineral processing equipment at ZONEDING, we have helped clients worldwide set up efficient gypsum production lines. Understanding the journey from a simple rock to a valuable powder is the first step in starting a successful operation. This guide will walk you through the entire process, explaining each stage and the equipment you need to transform raw gypsum into a final, marketable product.

Gypsum is a soft sulfate mineral composed of calcium sulfate dihydrate. Its chemical formula is CaSO₄·2H₂O. This means each molecule of calcium sulfate is bonded with two molecules of water. This water is a key part of its chemistry and is crucial for the gypsum calcination process. You can find gypsum in nature as large, sedimentary rock deposits. But It often forms when saltwater lakes or seas dry up. And The mineral is typically white, colorless, or gray it can also be found in shades of pink, yellow, or brown due to impurities. It is very soft and can be easily scratched with a fingernail.

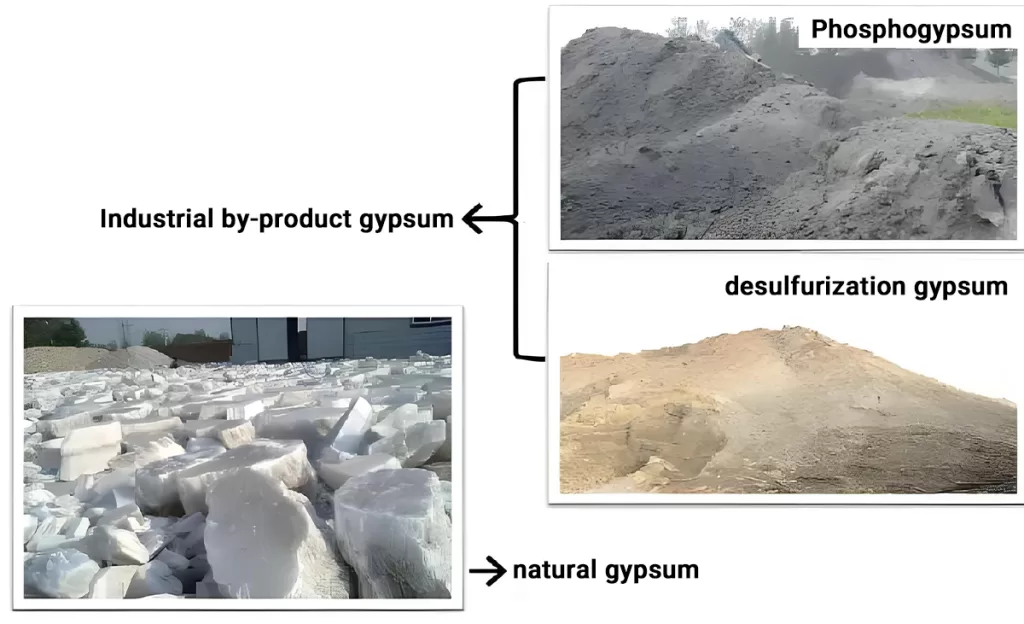

At ZONEDING, we deal with two main types of gypsum. The first is natural gypsum, which is mined directly from the earth. The second is synthetic gypsum, often called FGD gypsum, which is a byproduct of industrial processes like flue-gas desulfurization in coal-fired power plants. Both can be processed into high-quality products, but they require slightly different approaches and equipment.

The uses of gypsum are incredibly diverse, but they are dominated by the construction industry. The unique ability of its calcined form (Plaster of Paris) to harden after being mixed with water makes it extremely valuable.

The main application of gypsum is manufacturing drywall, also known as plasterboard or wallboard. Over 75% of all processed gypsum goes into making these panels that form the interior walls and ceilings of buildings worldwide. Its other applications are also very important for various industries.

| Industry | Application | Why Gypsum is Used |

|---|---|---|

| Construction | Drywall, Plaster of Paris, Stucco, Building Plasters | It is lightweight, easy to work with, provides a smooth finish, and offers fire resistance. |

| Cement | Additive in Portland Cement | It acts as a retarder, controlling the setting time of the concrete. Without gypsum, concrete would set too quickly. |

| Agriculture | Soil Conditioner (“Land Plaster”) | It improves soil structure, helps with water infiltration, and provides calcium and sulfur, which are essential nutrients for plants. |

| Other Uses | Molds for pottery, surgical splints, food additive | Its ability to form a hard, stable shape when set is used in many different fields. |

Raw gypsum rock is useful, but its true economic potential is unlocked through processing. The primary reason we process gypsum is to change its chemical structure through a process called calcination. This process is what gives gypsum its magical property of being able to set and harden.

The goal is to heat the gypsum to drive off about 75% of its bonded water. This transforms the calcium sulfate dihydrate (CaSO₄·2H₂O) into calcium sulfate hemihydrate (CaSO₄·½H₂O). This new substance is what we commonly know as Plaster of Paris. When you add water back to this powder, it rehydrates, crystallizes, and quickly turns back into a hard, solid mass of dihydrate gypsum. This reversible chemical reaction is the foundation of the entire gypsum industry. At ZONEDING, we design gypsum processing plants specifically to control this transformation perfectly.

A complete gypsum production line involves several key stages. Each stage requires specific machinery to reduce the size of the rock and then alter its chemistry. The process is straightforward and can be broken down into four main steps.

The process begins at the quarry. Gypsum is typically mined in open-pit mines. Large excavators and trucks are used to extract the raw gypsum rock from the deposit. The size of these rocks can be very large, often over 500mm, which is too big for any processing equipment.

The large rocks from the mine are transported to the crushing stage. This is the first step in size reduction.

After crushing, the gypsum pieces are still too large for efficient calcination. The material is fed into a grinding mill to be turned into a fine powder. A Ball Mill or a Raymond mill is commonly used. The goal is to produce a consistent, fine powder (around 100-200 mesh). This fine powder has a large surface area, which allows it to be heated evenly and quickly in the next stage.

This is the most critical step in the entire process. The fine gypsum powder is fed into a calciner, which is usually a large Rotary Kiln. Inside the kiln, the powder is heated to a precise temperature, typically between 140°C and 180°C. This controlled heating removes most of the water of crystallization, creating the final product: Plaster of Paris.

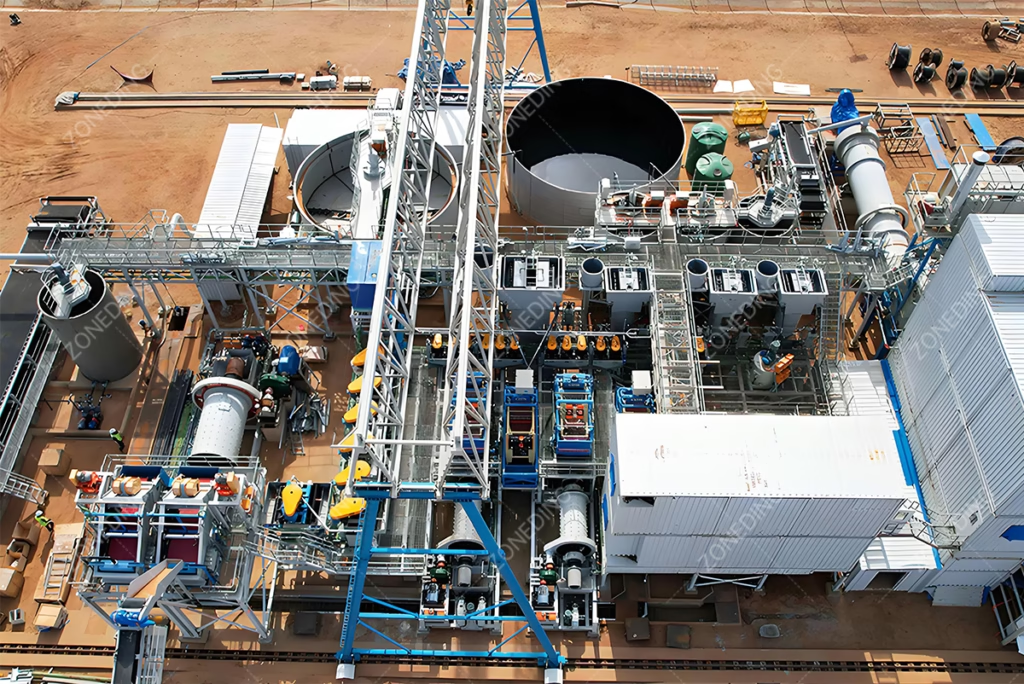

To build a full gypsum processing plant, you need a series of machines that work together in a continuous flow. As a manufacturer, we at ZONEDING provide the entire suite of equipment required.

While the final product can be very similar, the starting point for natural and FGD (Flue-Gas Desulfurization) gypsum is different, which affects the production line.

The gypsum price per ton can vary based on several market and production factors. If you plan to sell gypsum powder, you need to understand these factors.

Whether you are buying raw gypsum rock or selling finished powder, quality is key. Here is what to look for:

Controlling the final product quality happens during the production process. The most important variable to control is the calcination stage.

The key is precise temperature and time control in the rotary kiln.

At ZONEDING, our modern gypsum production lines include advanced control systems that monitor the temperature inside the kiln in real-time. This allows operators to make fine adjustments to the fuel flow and kiln rotation speed, ensuring every particle of gypsum is perfectly calcined. This level of control guarantees a consistent final product with a predictable setting time.

Gypsum production is a process of transforming a common rock into an indispensable industrial product. The journey involves powerful crushing, fine grinding, and a precise chemical transformation through heat. With the right equipment and process control, you can produce high-quality gypsum powder for a wide range of profitable applications.

At ZONEDING, we are more than just an equipment supplier; we are your partner in building a successful gypsum processing plant. Because we are a factory-direct manufacturer, we control the quality of every machine we build and can offer you a competitive price by eliminating middlemen. Our team of experienced engineers will work with you to design a customized production line tailored to your specific raw material and output goals. From initial design and manufacturing to on-site installation and training, we provide a complete, one-stop solution to get your operation running efficiently.

Contact us today to discuss your project and get a custom quote for your gypsum production line.

You see quartz every day, but you probably do not recognize it. It is in the glass of your phone screen and the windows of your house. It is even in the countertop in your kitchen. Raw quartz stone from the ground is not ready for these jobs. It ...

View detailsThe performance of your entire crushing plant hinges on one simple principle: consistent and controlled feeding. A primary crusher that is alternately for rock and then suddenly slug-fed with a massive, un-screened load is an inefficient one. Thi...

View detailsIf your crushed stone or gravel is full of clay, silt, and other debris, it is a big problem for your construction projects. Dirty aggregate leads to weak concrete and poor asphalt bonding, which can cause structures to fail. The solution is coar...

View detailsAre you watching your profits wash away with your wastewater? In many sand washing plants, a significant amount of fine sand (75 microns / 200 mesh and smaller) escapes with the overflow water. This isn't just waste; it's lost product and lost re...

View details