全站搜索

Search the entire website

Search the entire website

In your mining or aggregate operation, managing water is not just an operational task—it is a core driver of your profitability. Excess water in your product inflates shipping costs, reduces material quality, and creates significant safety risks. Effective mine dewatering transforms this liability into an asset, directly boosting your bottom line. This process is the critical step between a wet, low-value slurry and a dry, high-value, saleable product.

Dewatering in mining is the process of removing water from a mixture of solid particles and liquid. Imagine wringing out a saturated sponge—dewatering does the same thing for mined materials, but on an industrial scale. In many mineral processing circuits, water is used for washing, sorting, and transporting materials like sand, coal, or mineral concentrates. This creates a “slurry,” which is simply your valuable solid product suspended in a large volume of water.

The primary goal of slurry dewatering is to separate the solids from the water as efficiently as possible. This makes the final product easy to handle, convey, and transport. It also allows you to recover and recycle the process water, a critical part of modern mining water management. While you could leave a stockpile to drain naturally, this is slow, inefficient, and occupies a huge amount of space. Mechanical dewatering uses specialized equipment to rapidly and consistently remove water, preparing your product for immediate sale.

Ignoring proper dewatering is like actively choosing to reduce your profits. The importance of dewatering in mining cannot be overstated. It impacts everything from your daily operational costs to your long-term environmental liability. When you manage water effectively, you unlock efficiency gains across your entire operation. Here are seven critical reasons why dewatering in mining is essential.

You are paying to ship a product by weight, and water is heavy. Every percentage point of moisture in your final product is dead weight that costs you money to transport but earns you zero revenue. Consider this: a 40-ton truck loaded with sand that has 25% moisture content is carrying 10 tons of water. By using a ZONEDING dewatering screen to reduce that moisture to a “drip-free” 15%, you’ve removed 4 tons of water. For every single truckload, you save the cost of shipping 4 tons. If you ship 20 trucks a day, you save on shipping 80 tons of water daily. This is a direct and immediate saving that goes straight to your bottom line.

Your customers buy solids, not water, and they have strict quality specifications. In industries like concrete and asphalt production, the water-to-cement or water-to-bitumen ratio is critical for final product strength and durability. A product with inconsistent or high moisture content is considered low-grade and can be rejected at the plant gate. By dewatering your material to a consistent, low moisture level, you produce a premium, ready-to-use product that commands a higher price. It also handles better, flows reliably from silos, and won’t freeze into a solid block in cold weather, making it more valuable to your end-users.

Wet, sloppy material is difficult to handle and causes plant bottlenecks. Slurry and high-moisture solids stick to conveyor belts, build up in transfer chutes, and can blind sizing screens downstream. This leads to frequent, unscheduled downtime for cleanup, reducing your plant’s overall throughput. Dewatered material is free-flowing and easy to convey. It moves cleanly from one stage to the next, allowing your entire circuit to run at its designed capacity. This increased uptime and efficiency mean more tons of saleable product produced per hour.

Wet material requires huge areas for draining and storage. When you dump wet slurry into a stockpile, it creates a soupy, unstable pile that can take weeks to drain naturally. These massive settling ponds consume valuable land on your site. Dewatered material, on the other hand, can be stockpiled immediately. The piles are stable, have a steeper angle of repose, and require a much smaller footprint. This frees up valuable land for other operational needs and allows for faster inventory turnover, as the product is ready for sale almost immediately after production.

Tailings dewatering is one of the most critical environmental and safety processes in modern mining. Tailings are the fine waste particles left over from mineral processing. Storing them as a wet slurry in massive tailings dams poses a significant and well-documented risk of catastrophic failure. By using tailings dewatering equipment like a filter press or thickeners, you transform the slurry into a dense, semi-solid “cake.” This material can be transported by truck and stacked in a much smaller, more stable landform known as “dry stacking.” This massively reduces the risk and long-term liability of your operation, protecting both the environment and your company’s reputation.

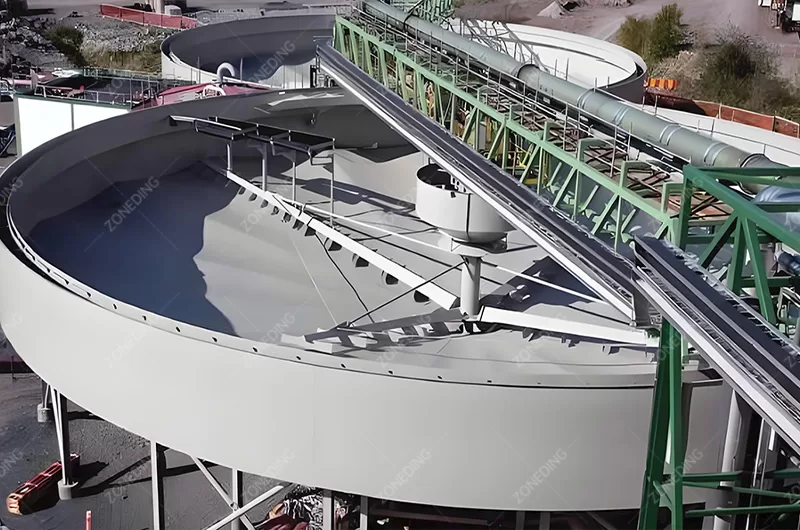

Water is a finite and often expensive resource, essential for your operation. An effective dewatering circuit is also a water recovery circuit. The water removed from your solids can be captured, clarified in tanks, and pumped back to the start of your wash plant. This creates a closed-loop system that can reduce your fresh water intake by over 90%. This not only cuts your costs for purchasing and pumping water but also makes your operation more sustainable. It demonstrates responsible mining water management and makes your site more resilient to drought and water-use regulations.

Compliance with environmental laws is non-negotiable. Government agencies worldwide are enforcing stricter rules on water discharge and site runoff. Discharging untreated process water can lead to heavy fines and even the suspension of your operating license. A well-designed mine dewatering system minimizes the water you discharge. Furthermore, by creating stable, dewatered stockpiles, you significantly reduce the risk of contaminated runoff from rain, preventing pollutants from entering local streams and groundwater. This proactive approach to environmental management ensures you remain compliant and maintain your social license to operate.

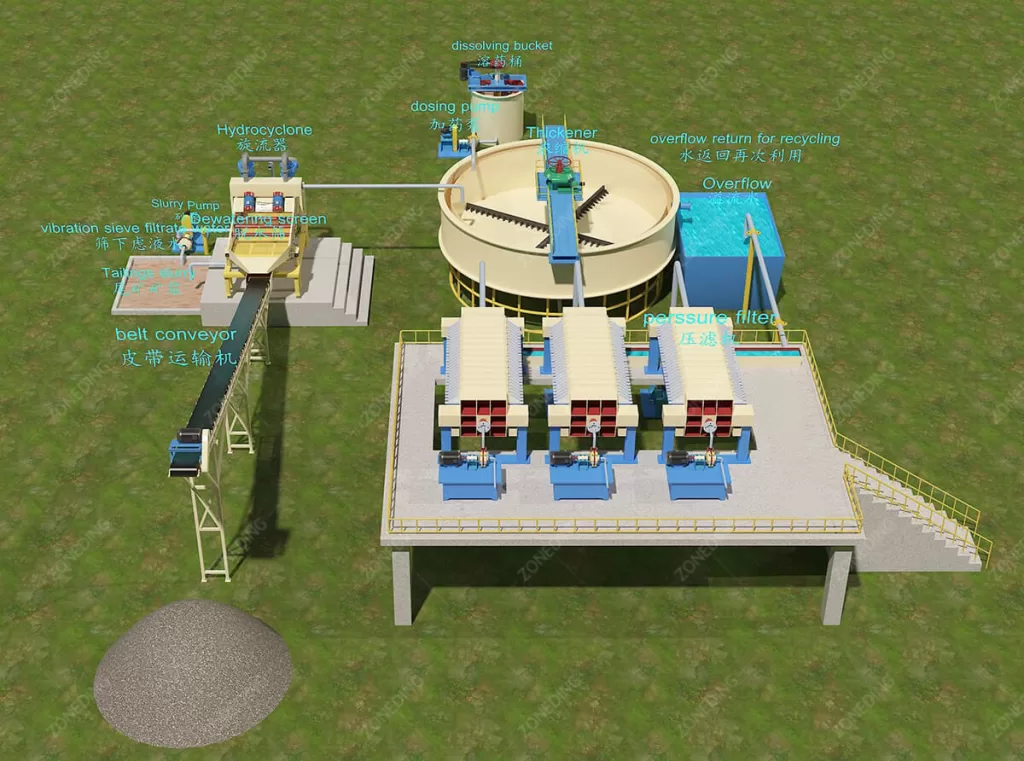

There are several mine dewatering methods, each suited for different materials and final moisture requirements. The key is choosing the right tailings dewatering equipment for your specific application.

Here are some of the biggest applications:

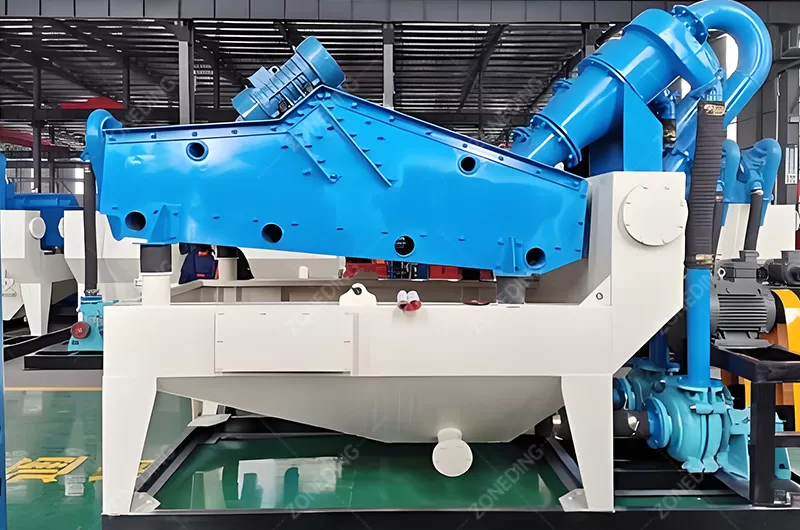

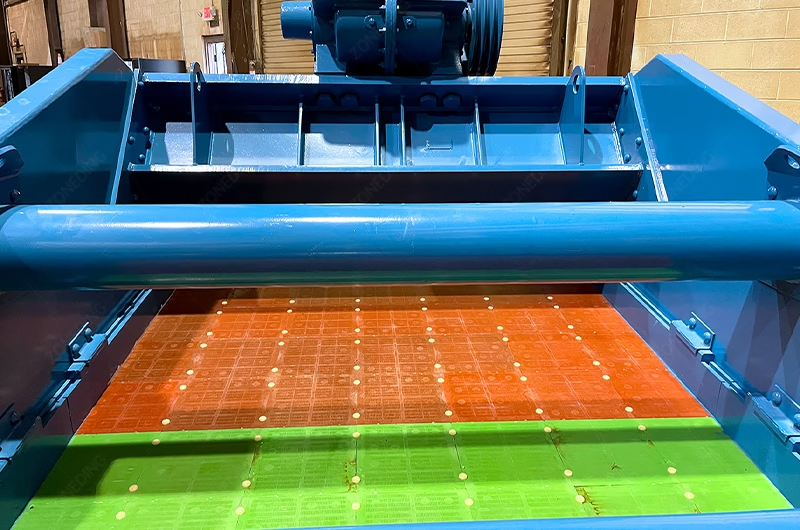

This is the workhorse for dewatering sand, aggregates, coal, and other granular materials. A dewatering screen uses high-frequency vibration to separate water from solids.

A filter press is used when you need to achieve the lowest possible moisture content, especially with very fine materials. It uses high pressure to squeeze water out of a slurry between filter plates.

Thickeners and Clarifiers are large tanks that use gravity to settle solids out of a slurry. Flocculants are often added to help fine particles clump together and settle faster. They are typically used as a pre-dewatering step to increase the slurry density before it feeds a filter press or dewatering screen, and to clarify the recycled water.

Centrifuges use high-speed rotation to generate G-force that separates solids from liquids. They are effective for fine slurries but are known for high energy consumption and intensive maintenance requirements.

A dewatering screen works by using linear motion and an uphill slope to force water out while conveying solids forward. Unlike a standard sizing screen that slopes downhill, a dewatering screen is installed at a slight incline (around 5 degrees uphill).

Choosing the right dewatering screen is an engineering decision, not a simple purchase. You need to match the machine to your specific material and goals.

The price of a dewatering screen can range from approximately $10,000 for a small unit to over $100,000 for a large, high-capacity machine. It is not a one-size-fits-all product, and the cost depends on several key factors:

Think of it as an investment with a clear ROI. The daily savings in transport costs and the increased value of your product often mean a dewatering screen can pay for itself in a matter of months.

Proper maintenance is key to ensuring a long and productive life for your equipment. Dewatering screens are robust, but they operate in harsh conditions. Here is a simple maintenance schedule to follow:

ZONEDING provides detailed maintenance manuals and full after-sales support to ensure you get the maximum uptime from your investment.

The field of mineral processing water removal is constantly evolving. The latest trends for 2025 focus on intelligence, efficiency, and sustainability.

Choosing the right partner is as important as choosing the right equipment. ZONEDING, established in 2004, is not just a vendor; we are your factory-direct manufacturing partner.

Effective mine dewatering is not an operational expense; it is a direct investment in your profitability. By removing excess water, you immediately cut transportation costs, improve your product’s market value, increase operational efficiency, ensure a safer site, and operate more sustainably. For most granular materials, the dewatering screen offers the most efficient, reliable, and cost-effective solution.

Making the switch from passive draining to active mechanical dewatering is a strategic decision that pays dividends every single day. The key is to partner with a manufacturer who can provide a robust, properly engineered solution tailored to your unique operational needs.

Ready to stop paying to ship water and start maximizing your profits? Contact the ZONEDING engineering team for a free consultation on your dewatering project.

Choosing the right rock crusher is the single most important decision for your quarry, mining, or recycling operation. It's the engine of your business. The right choice maximizes your output and profit, while the wrong one leads to constant head...

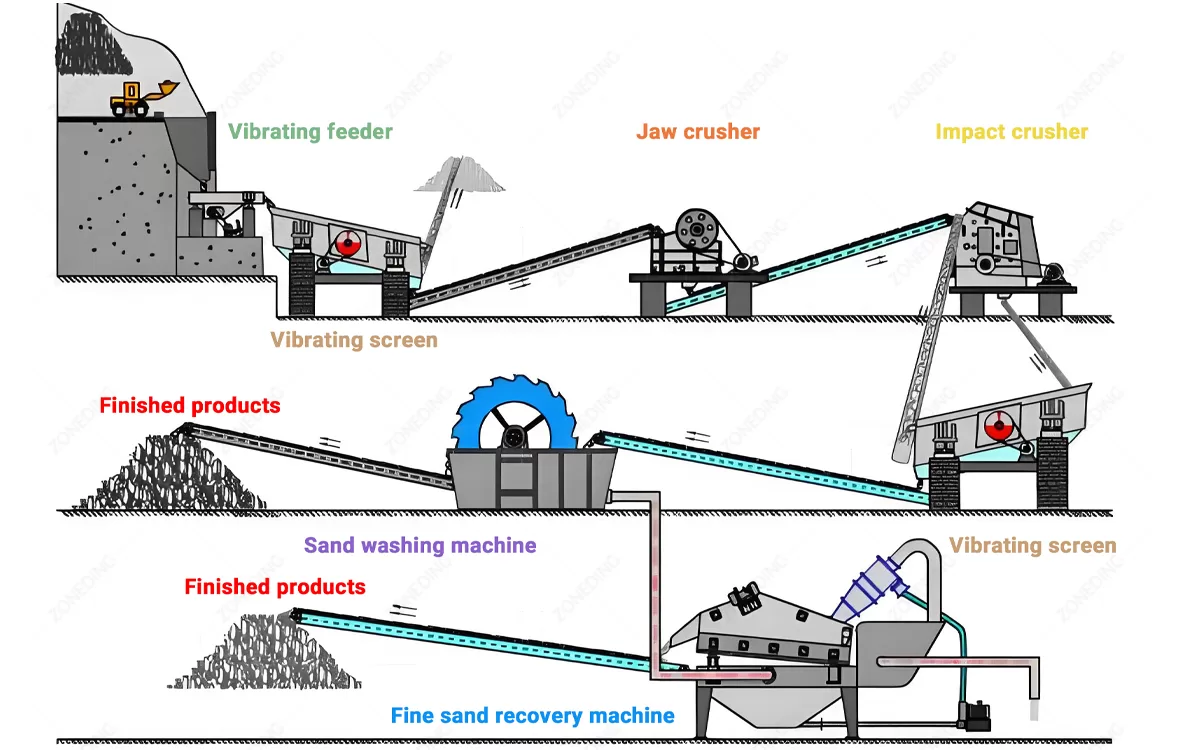

View detailsThe crushing process is the heart of turning large, unusable rock into valuable, specific-sized products like sand and gravel. The goal of any rock crushing plant is to reduce the size of raw material through a series of stages to produce aggrega...

View detailsAre you struggling with inefficient mineral separation, leaving valuable materials behind? Are you experiencing low recovery rates and high operating costs? This comprehensive guide will give all the details about shaking tables. Shaking...

View detailsYour cone crusher is the heart of your operation. And its heart is made of steel. Specifically, the Cone Crusher Liner set is where all the work happens. Choosing the right liners, and knowing when and how to change them, is not just maintenance....

View details