全站搜索

Search the entire website

Search the entire website

Choosing the right cone crusher is a big decision for your quarry or aggregate production business. This machine is the heart of your secondary and tertiary crushing stages, turning rock into valuable, specific-sized products. A good choice boosts your profit, while a bad one creates bottlenecks and high costs. At ZONEDING, we have helped hundreds of clients find the perfect fit since 1990. This guide will help you understand the options so you can make a smart choice for your operation.

A cone crusher is a compression-type machine that reduces rock by squeezing it. It does not smash rock with impact like an impact crusher. Instead, it crushes material between a rotating piece of steel (the mantle) and a stationary piece of steel (the bowl liner or concave). This machine is a key player in the middle stages of a crushing plant. It takes the larger rock that has already been broken down by a primary jaw or gyratory crusher and makes it much smaller, preparing it for final sizing by a screen or a tertiary crusher. The main goal is to create smaller, well-shaped (cubical) aggregate, which is exactly what concrete and asphalt producers want.

Imagine holding a nut in a metal bowl and using another cone-shaped piece of metal to roll around inside the bowl, cracking the nut against the sides. A cone crusher works in a very similar way. The process is simple but very effective.

Rock is fed into the top of the crusher. Inside, a cone-shaped mantle gyrates, or wobbles, in an eccentric path. It does not spin, but it moves in a circular motion. As the mantle moves toward the stationary bowl liner, it squeezes and crushes the rock. As it moves away, the crushed material falls further down into the chamber. This cycle happens very quickly. The gap at the bottom of the crushing chamber is called the Closed Side Setting (CSS). The CSS determines the maximum size of the material that comes out. You can adjust this gap to produce different sizes of aggregate.

There are several types of cone crushers, and each is designed for slightly different jobs. The main differences are in how they are supported, how they handle overload situations (like a piece of uncrushable steel getting in), and how they are adjusted. Understanding these types is the first step in choosing the right machine for your aggregate production.

This is the classic, original design for spring cone crushers. It uses a set of heavy-duty springs on the outside of the machine to protect it from damage. If a piece of metal or extremely hard rock enters the crusher, the springs compress, allowing the bowl to lift up and let the object pass through.

Advantages:

Applications:

They are excellent for small to medium-sized quarries and mining operations, especially where budgets are tight and advanced automation is not a priority. They perform well in secondary crushing applications with medium-hard rocks.

This is a more modern design that replaces the springs with a single large hydraulic cylinder cone crusher at the bottom of the crusher. This cylinder supports the main shaft and is used for both adjusting the CSS and providing overload protection.

Advantages:

Applications:

This is a very popular choice for a wide range of applications, from crushing hard rock like granite to processing river stone. It is a versatile workhorse for secondary and tertiary crushing stages in modern plants.

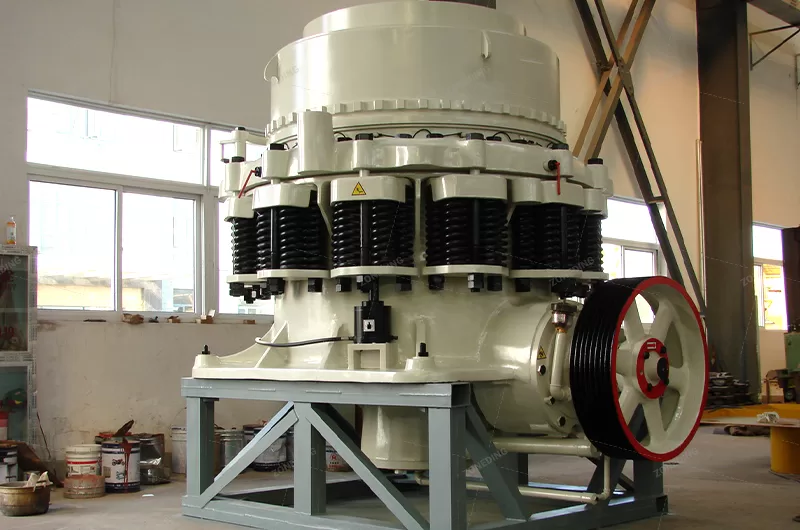

This is the high-performance option. It uses multiple hydraulic cylinders around the base of the crusher. These cylinders handle both adjustment and overload protection. The design also features a fixed main shaft, which makes the structure very stable.

Advantages:

Applications:

This is the best choice for high-capacity quarries and mines that process very hard and abrasive materials like basalt, granite, or iron ore. It is the top performer for producing premium aggregates.

A gyratory crusher works on the same principle as a cone crusher, but it is much, much larger. It is almost always used as a primary crusher, not a secondary one. It has a less steep crushing head than a cone crusher, allowing it to accept very large feed sizes directly from the quarry.

Advantages:

Applications:

These are only found in very large-scale mining operations and the biggest quarries in the world, where production demands are massive.

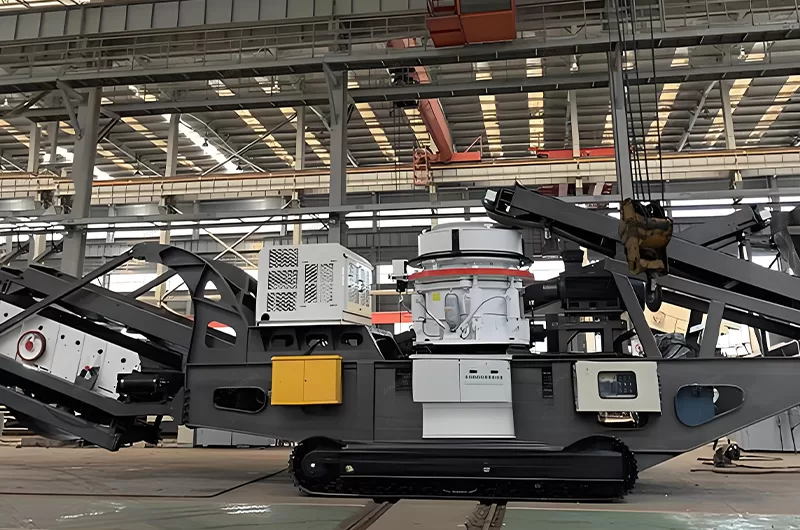

This is not a different type of crushing mechanism, but a platform. A mobile cone crusher is a single-cylinder or multi-cylinder hydraulic unit mounted on a tracked chassis. This creates a self-contained, movable crushing plant.

Advantages:

Applications:

This is ideal for contractors, recycling operations, and quarries that need to move their crushing operations frequently. It is a key component of a complete mobile crushing and screening plant.

The biggest evolution in cone crusher technology has been the shift from springs to hydraulics. While spring crushers are still reliable, hydraulic cone crushers offer major advantages for most modern operations. The core difference is how they handle adjustments and protect themselves from damage.

With a spring crusher, you have to manually tighten or loosen huge bolts to change the CSS. For overload protection, the springs physically compress. This works, but it can be slow and less precise. A hydraulic system uses oil pressure to do everything. You can adjust the CSS from a control panel in minutes. For overload, the hydraulic system allows oil to be released from the cylinder, letting the uncrushable object pass, and then it automatically returns to the previous setting. This means less downtime, better safety for your crew, and more consistent product size. For most new plants, a hydraulic crusher is the smarter long-term investment.

Both single-cylinder and multi-cylinder are types of hydraulic cone crushers, but the multi-cylinder design is generally considered more advanced and high-performing. A single-cylinder crusher supports the main shaft assembly from one large cylinder at the bottom. This is a simpler and very robust design.

A multi-cylinder crusher has a main shaft that is fixed in place. The bowl assembly moves up and down for adjustment, pushed by several hydraulic cylinders. This design provides more uniform support and allows for a much larger crushing force to be applied. The result is higher throughput, a better reduction ratio, and a more cubical final product. If you are processing very hard rock or have strict specifications for your final product shape, a multi-cylinder hydraulic crusher is the superior choice. If you need a reliable, modern, and slightly more economical option, the single-cylinder is an excellent machine.

The type of rock you are crushing is the most important factor in your decision. Different rocks have different hardness and abrasiveness, which affects how they break and how quickly they wear down your machine’s parts.

At ZONEDING, we understand that your equipment is the heart of your operation. We provide complete, reliable solutions for your limestone crushing plant.

limestone crusher machine to the final conveyors. This ensures all the parts work together perfectly.The price of a cone crusher can range from as low as $30,000 for a small, Chinese-made spring cone crusher to over $500,000 for a large, high-capacity multi-cylinder hydraulic crusher from a top global brand. This wide range is due to several factors.

At ZONEDING, we build our cone crushers to be reliable, efficient, and easy to maintain. We combine proven designs with high-quality components to give you the best value.

Choosing the right cone crusher comes down to matching the machine’s technology to your rock type, production goals, and budget. For hard rock and high-capacity needs, a multi-cylinder hydraulic crusher is the top choice. For all-around versatility and modern performance, a single-cylinder hydraulic crusher is an excellent investment. The classic spring cone crusher remains a solid, low-cost option for smaller operations with less demanding materials.

Your next step should be to clearly define your needs. Know your feed material, the input and output sizes you require, and your target tons per hour. With this information, you can have a productive conversation with an equipment expert who can guide you to the perfect model.

Contact us today to discuss your project. Our engineers are ready to help you select the cone crusher that will make your quarry more profitable.

Water is one of the most valuable resources at any mine site. Managing it effectively is key to profitability and environmental responsibility. Mining Thickeners are the workhorses that make this possible. They are large, circular tanks designed ...

View detailsYou see quartz every day, but you probably do not recognize it. It is in the glass of your phone screen and the windows of your house. It is even in the countertop in your kitchen. Raw quartz stone from the ground is not ready for these jobs. It ...

View detailsThis guide provides a comprehensive look at jaw crushers, covering everything from their core mechanics and common uses to the latest advancements and essential selection criteria, equipping you with the knowledge to leverage this technology effe...

View detailsChoosing the right rock crusher is a major decision for your quarry or mining operation. The wrong choice can lead to wasted money, inefficient production, and lower profits. Jaw crushers and impact crushers are two of the most common types of cr...

View details