Choosing the right rock crusher is the single most important decision for your quarry, mining, or recycling operation. It’s the engine of your business. The right choice maximizes your output and profit, while the wrong one leads to constant headaches, high operating costs, and poor product quality. With so many rock crusher types available, the options can feel overwhelming. At ZONEDING, we’ve been manufacturing and designing complete crushing plants since 1990, and we want to share our knowledge to help you make a confident, profitable decision.

Table of Contents

Why is Choosing the Right Crusher So Critical?

The crusher you choose directly impacts your bottom line every single day. It’s not just about breaking big rocks into small ones. A well-matched crusher gives you higher production rates, meaning more sellable product per hour. It produces a better-shaped final product (cubical shape), which commands a higher price. It also lowers your cost per ton by minimizing wear and tear on parts and reducing energy consumption. A mismatched machine does the opposite: it creates production bottlenecks, wears out expensive parts quickly, and produces low-quality aggregate that is hard to sell. This guide will help you understand the different rock crusher types to avoid those costly mistakes.

What are 7 Different Types of Rock Crushers?

Rock crushers are generally categorized by their crushing mechanism: compression or impact. Understanding how each one works is key to matching it with your specific rock and production goals. Let’s break down the main types.

Jaw Crusher

- what is a jaw crusher?

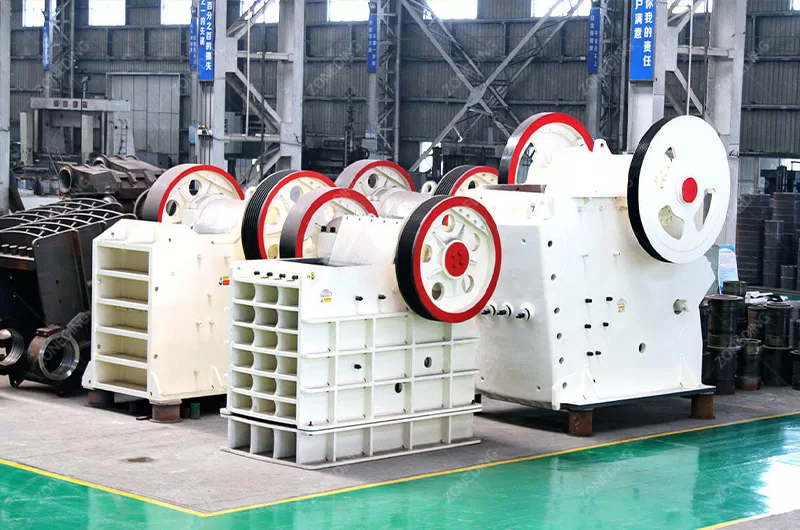

- The jaw crusher is the workhorse of the crushing industry. It is a primary crusher that uses compression to break rock.

- When do you need a jaw crusher?

- You need a jaw crusher at the very beginning of your crushing circuit. It’s designed to take large, blasted rock and reduce it to a size that a secondary crusher can handle.

- Applicable Materials for jaw crushers

- It excels at crushing very hard, abrasive materials like granite, basalt, iron ore, and river stone.

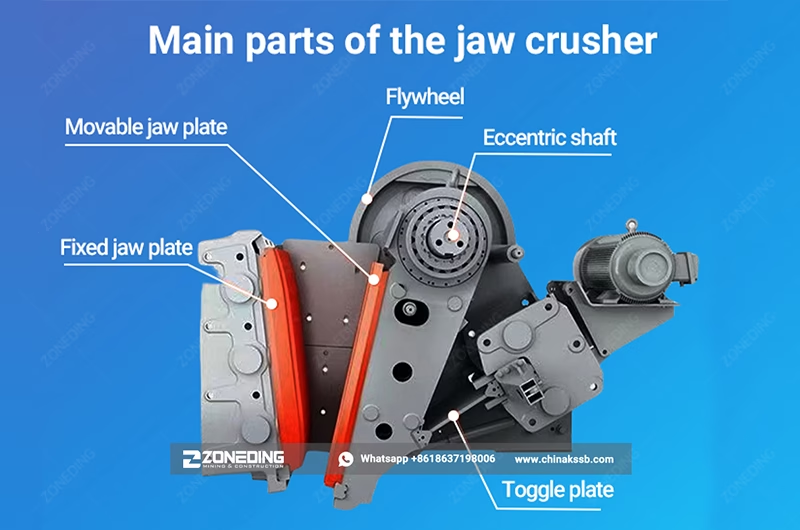

- How does the jaw crusher work?

- Imagine a giant mechanical jaw. Rock is fed between a stationary jaw plate and a moving jaw plate. The moving jaw applies immense force, squeezing and breaking the rock. As the jaw opens, the smaller material falls down, ready for the next cycle, until it is small enough to exit the bottom.

- what is the price of a jaw crusher

- Jaw crushers offer excellent value. They are robust, simple, and have a lower initial cost compared to other primary crushers like gyratories. A small unit might start around $1500, while large, high-capacity models can exceed $200,000.

Cone Crusher

- What is a cone crusher?

- The cone crusher is a compression-style crusher used mainly for secondary and tertiary crushing.

- When do you need a cone crusher?

- You use a cone crusher after a jaw crusher. Its job is to take the pre-crushed rock and reduce it to much finer sizes, like the aggregate needed for concrete or asphalt base layers.

- Applicable Materials for cone crushers

- Like the jaw crusher, it is ideal for hard and abrasive materials, including granite, basalt, and various ores. It’s the standard choice for secondary crushing in hard rock applications.

- How does the cone crusher work?

- Material is fed into the top. Inside, a cone-shaped mantle gyrates (wobbles) inside a stationary bowl liner. This motion continuously squeezes and crushes the rock as it moves down the chamber. The final product size is controlled by the gap at the bottom.

- what is the cost of cone crushers?

- Cone crushers are more complex and therefore more expensive than jaw crushers. Prices can range from $20,000 for smaller spring models to over $300,000 for advanced multi-cylinder hydraulic units.

Impact Crusher

- What is a impact crusher?

- An impact crusher uses the principle of high-speed impact, not compression, to break rock. It’s known for producing a superior, cubical product shape.

- When do you need a impact crusher?

- You can use it as a primary or secondary crusher. It’s an excellent choice when product shape is more important than just size reduction, or when working with less abrasive materials.

- Applicable Materials for impact crushers

- It is best for medium-hard to soft materials like limestone, dolomite, and is the best rock crusher for construction waste recycling because it handles rebar well.

- How does the impact crusher work?

- Rock is fed into the crushing chamber and hit by rapidly spinning hammers or “blow bars” mounted on a rotor. The rock shatters and is thrown against stationary “impact plates,” breaking it further.

- what is the cost of impact crusher?

- The initial cost is often similar to a cone crusher. However, the operating cost can be higher with abrasive materials because the blow bars wear out faster than cone liners.

Hammer Crusher

- What is a hammer crusher?

- A hammer crusher, or hammer mill, is a simpler type of impact crusher.

- When do you need a hammer crusher?

- It’s used for primary and secondary crushing of materials that are not very abrasive. It’s a good choice for smaller-scale operations with a limited budget.

- Applicable Materials for hammer crushers

- It works best on brittle, low-abrasion materials such as coal, limestone, gypsum, and salt.

- How does the hammer crusher work?

- A high-speed rotor is fitted with swinging hammers. As material enters, the hammers strike it, shattering it against a solid plate or grate bars at the bottom, which control the output size.

- what is the cost of hammer crusher?

- Hammer crushers are one of the most affordable rock crusher types, making them a great entry-level option for suitable applications. Price range of hammer mill is from USD1,300-USD40,000.

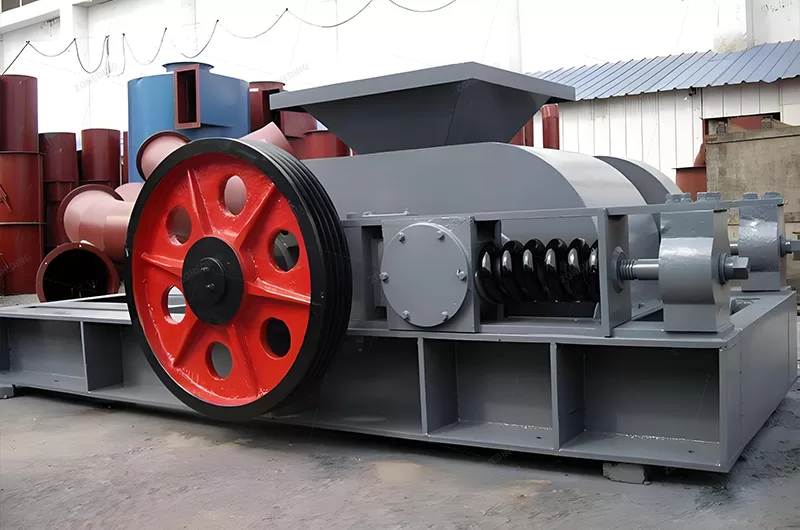

Roll Crusher

- What is a roll crusher?

- A roll crusher is a compression crusher that uses two large cylinders to break material.

- When do you need a roll crusher?

- It is typically used for secondary or tertiary crushing of minerals and soft to medium-hard rock where a very specific, narrow product size is needed with minimal fines.

- Applicable Materials for roll crushers

- It’s effective on materials like coal, clay, phosphate, and limestone. It can also handle sticky materials that might clog other crushers.

- How does the roll crusher work?

- Material is fed into the gap between two heavy, counter-rotating rollers. The rock is pulled into the gap and crushed as the rollers turn. The gap between the rollers determines the final product size.

- what is the cost of roll crusher?

- The price is moderate and highly dependent on the size and specific design for the application. The small roll crusher is about USD4,000. And the larger will be more higher in price, about USD30,000.

VSI Crusher (Vertical Shaft Impactor)

- What is a VSI Crusher?

- The VSI is a highly specialized impact crusher, often called a “sand making machine.” Its main purpose is shaping, not just size reduction.

- When do you need a VSI Crusher?

- You use a VSI in the final stage of crushing (tertiary or quaternary) to produce perfectly shaped, cubical fine aggregate or manufactured sand.

- Applicable Materials for VSI Crushers

- It can handle a wide range of materials. A key feature is its “rock-on-rock” crushing process, where rock is thrown against a bed of the same material, reducing wear on the machine itself.

- How does the VSI Crusher work?

- Material is fed into the center of a high-speed rotor. Centrifugal force throws the material outwards at very high velocity. It then smashes against other rocks in the crushing chamber, causing it to break along natural fissures, creating a superior cubical shape.

- what is the cost of VSI Crusher?

- VSI crushers are a significant investment, reflecting their specialized role in producing premium products.Price is from USD10,000-USD43,000

Gyratory Crusher

- What is a Gyratory Crusher?

- A gyratory crusher is a very large primary crusher that operates on the same principle as a cone crusher.

- When do you need a Gyratory Crusher?

- You only need this machine for extremely high-capacity operations, such as large-scale mines that process thousands of tons per hour.

- Applicable Materials for Gyratory Crushers

- It can handle any type of rock and is fed directly by large mining trucks.

- How does the Gyratory Crusher work?

- It has a cone-shaped crushing head that gyrates within a concave bowl. Because it can be fed from all sides and has a larger crushing chamber, its capacity is much higher than a jaw crusher.

- what is the cost of Gyratory Crusher?

- This is the most expensive type of crusher, with prices starting in the high hundreds of thousands and going into the millions of dollars.

Primary vs. Secondary Crushers: What’s the First Step?

Understanding the stages of crushing is essential. A crushing plant is not a single machine but a system.

- Primary Crushing: This is the first step. The goal is to take large, run-of-mine rock and break it down to a manageable size. Jaw crushers and gyratory crushers are primary crushers.

- Secondary Crushing: This stage takes the output from the primary crusher and reduces it further. Cone crushers and impact crushers are the most common secondary crushers.

- Tertiary/Quaternary Crushing: These are the final stages, focused on producing specific final products, like manufactured sand or finely graded aggregates. VSI crushers and specialized cone crushers are used here.

Your first decision is always the primary crusher, as its output determines what kind of secondary crusher you will need.

Need Perfect Cubical Shape? Is an Impact Crusher the Answer?

Yes, for many applications, an impact crusher is the best answer for creating a cubical product. Cubical, or well-shaped, aggregate is stronger and preferred for making high-quality concrete and asphalt. Compression crushers like jaws and cones can sometimes produce more flaky or elongated particles. Impact crushers break rock along its natural cleavage planes, resulting in a more uniform, cubical shape. If your customers have strict shape specifications, an impact crusher or a VSI in the final stage is often a necessary investment.

How to Choose the Right Rock Crusher for Your Plant?

Here is a simple, step-by-step process to guide your decision:

- Analyze Your Rock: First, what are you crushing? Is it hard and abrasive like granite, or soft like limestone? This is the most critical question.

- Define Your Capacity: How many tons per hour (TPH) do you need to produce? Be realistic about your current needs and future growth.

- Determine Feed and Product Sizes: What is the maximum size of the rock going into your crusher? What are the final product sizes you need to sell?

- Set Your Budget: Consider both the initial purchase price and the long-term operating costs, especially for wear parts.

- Consult an Expert: Talk to an experienced manufacturer like ZONEDING. We can run simulations and analyze your material to recommend the most efficient and cost-effective rock crusher types for your specific project.

Why Choose a Complete ZONEDING Crushing Line?

Buying a single machine is just one piece of the puzzle. A complete crushing plant includes feeders, crushers, screens, and conveyors that must all work together perfectly. When you partner with ZONEDING for a complete line, you get a system where every component is perfectly matched. This eliminates bottlenecks, maximizes efficiency, and simplifies maintenance. We design the entire plant based on your specific needs, ensuring a smooth workflow from raw rock to final product. This integrated approach is far more effective than trying to piece together equipment from different suppliers. We also offer mobile crushing plant solutions for maximum flexibility.

At ZONEDING, we’ve been building robust and reliable crushers since 1990. As a factory-direct manufacturer, we eliminate the middleman, offering you superior equipment at a more competitive price. Our machines operate in over 120 countries, proving their durability in the toughest conditions. We don’t just sell you a machine; we provide a complete solution, including plant design, installation, training, and lifetime support for spare parts. Our team of engineers is ready to help you build the most efficient and profitable crushing plant for your needs.

FAQ

- Q1: What is the main difference between a jaw crusher and a cone crusher?

- A jaw crusher is a primary crusher used for large feed sizes. A cone crusher is a secondary or tertiary crusher that takes the smaller material from the jaw crusher and refines it further. You almost always need a jaw crusher before a cone crusher in a hard rock application.

- Q2: What is the best rock crusher for granite?

- For granite, which is very hard and abrasive, the best combination is a jaw crusher for primary crushing followed by a cone crusher for secondary crushing. This setup is durable and efficient for tough materials.

- Q3: Can I use just one crusher for everything?

- Generally, no. A single crusher cannot efficiently take huge rocks and turn them into fine sand. Crushing is a multi-stage process, and using the right rock crusher types for each stage is key to efficiency and quality.

- Q4: What is the best rock crusher for construction waste?

- An impact crusher is typically the best choice for recycling concrete and asphalt. It produces a high-quality, cubical recycled aggregate and is better at handling contaminants like steel rebar than a cone crusher.

Summary and Final Advice

The journey to finding the right rock crusher starts with understanding your material and your goals. Jaw crushers are the universal starting point for hard rock. Cone crushers are essential for secondary reduction of that hard rock. Impact crushers are the champions of product shape and excel with softer materials and recycling. By carefully considering the factors we’ve discussed, you can select a machine that will be a profitable asset for years to come.

Your next step is to gather your project details: rock type, required TPH, and desired product sizes. Then, reach out to an expert who can help you navigate the options.

Contact us today for a free consultation and quote for your project.