全站搜索

Search the entire website

Search the entire website

Lead-zinc ore refers to the mineral deposits rich in the metallic elements lead and zinc. Lead and zinc has wide-ranging applications in such as electrical, mechanical, military, metallurgical, chemical, light, and pharmaceutical industries.

ZONEDING MACHINE. ZONEDING builds machines for mining. ZONEDING makes crushers and other equipment. Lead-zinc ore is important. It contains valuable metals, lead and zinc. It often has other metals too. Crushing lead-zinc ore has special challenges. You must break the rock to free the valuable minerals. This is called liberation. You need to do this well. But you also want to make as little fine dust as possible. Too much fine dust hurts the next step: flotation. A lead-zinc ore crushing plant needs to balance these things. It needs to free the minerals. It needs to control fine particles. Doing this well helps you recover more metal. This increases your profit. ZONEDING will explain how to crush lead-zinc ore effectively.

Here are very common lead-zinc ore crushing plants for reference. They have been proven by practice. And they have the advantages as follows:

Lead-zinc ore is complex. It is not just one mineral. It has lead minerals, usually galena. It has zinc minerals, usually sphalerite. These minerals are often mixed together in the rock. They are also mixed with waste rock. To get the lead and zinc, you must break the rock. You break it until the lead and zinc particles are separate from the waste. You also break them until lead particles are separate from zinc particles. This separating is called liberation.

Galena, the lead mineral, is often soft and brittle. This means it breaks easily. When you crush the ore, the galena tends to break into very small pieces. These very small pieces are called fines or slimes. Sphalerite, the zinc mineral, might break differently. The waste rock also breaks in its own way. All these different minerals breaking differently makes crushing lead-zinc ore hard. You want to break the rock enough to get good liberation. You want the lead and zinc particles to be free. But you do not want to break the soft galena into too many fines. This is the tricky part. Making too many fines causes problems later in the plant. This needs a careful balance. It is not just about making rock smaller. It is about breaking it in a controlled way to free the valuable minerals without making too much dust.

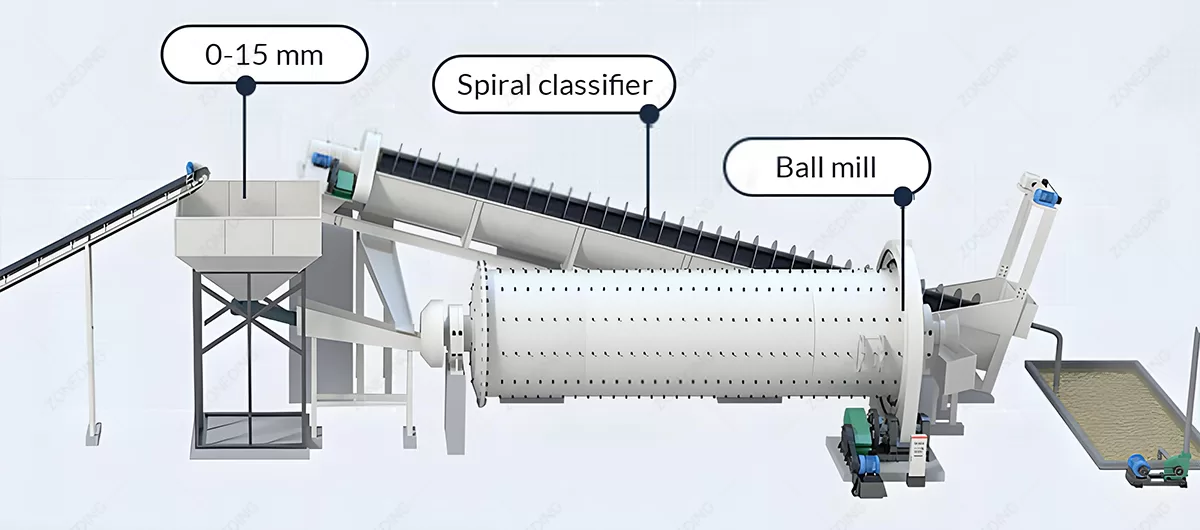

Designing the crushing process for lead-zinc ore is important. The goal is to get the minerals free. You want to do this with as few fines as possible. The crushing plant prepares the material for the next stage. This next stage is usually grinding (Ball Mill or Rod Mill). After grinding, the ore goes to flotation (Flotation Machine). Flotation separates the lead and zinc from the waste. It also separates lead from zinc.

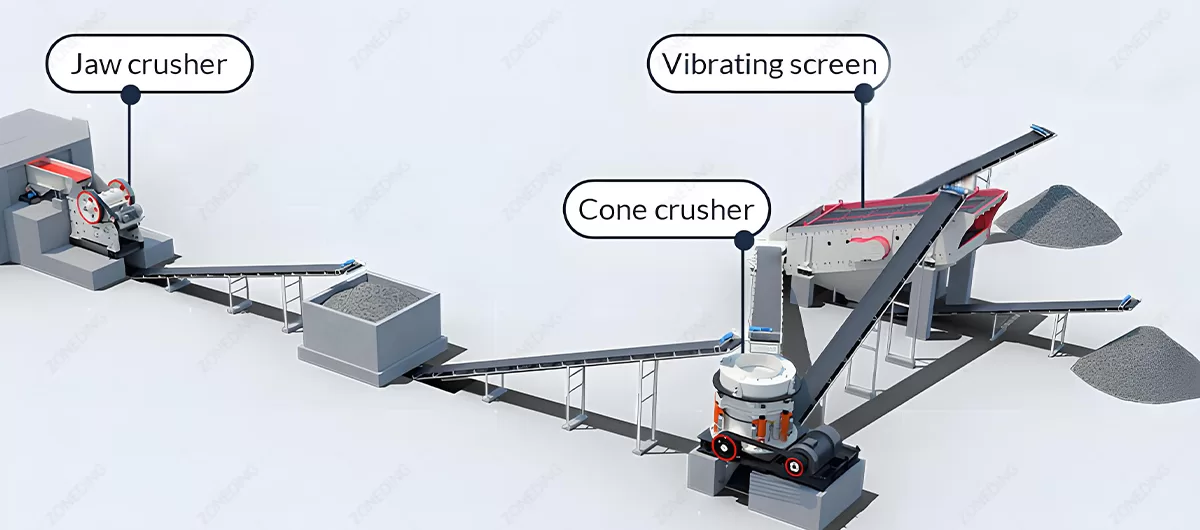

A good crushing process uses multiple steps. First, a primary crusher takes big rocks. Then, secondary and maybe tertiary crushers break the rock smaller. After each crushing step, the material goes to a screen (Vibrating Screen or High-Frequency-Screen). The screen sorts the rock by size. Pieces that are small enough go to the next step (maybe grinding). Pieces that are too big go back to a crusher. This is called closed-circuit crushing. This loop helps control the final size. It reduces crushing of material that is already small enough. This helps reduce fines. Using feeders (Vibration Feeder) that give a steady flow to the crushers also helps. It stops crushers from getting overloaded. Overloading can make more fines. The process design must consider how easily the minerals become free. Some ores need less crushing to free minerals. Some need more. The design should match the ore’s specific needs.

Choosing the right machines for your lead-zinc ore crushing plant is very important. Not all crushers are the same. Different types break rock in different ways. Some are better at reducing size. Some are better at making a more even product. Some make more fines than others. You need a combination that works well for lead-zinc ore.

For the first step, handling big rocks from the mine, a Jaw Crusher is usually the primary crusher. It breaks rock by squeezing it between two plates. Jaw crushers are strong. They can take large feed sizes. They are reliable. After the jaw crusher, you need to break the rock smaller. A Cone Crusher is a common choice for secondary or tertiary crushing. Cone crushers also squeeze rock. They are good at making a more uniform product size. They can be adjusted to change the output size. Compared to impact crushers, cone crushers often make fewer fines when crushing hard or brittle rock like some lead-zinc ores. Impact crushers (Impact Crusher) hit the rock with hammers. They are good for some rocks, but can make a lot of fines with brittle ores. So, a cone crusher is often preferred for lead-zinc.

Screens (Vibrating Screen) are essential partners to crushers. They separate sizes. For finer screening needed before grinding, a High-Frequency-Screen might be used. This screen vibrates very fast. It helps fine particles pass through. This makes sure the material going to the grinding mill (Ball Mill) is not too big. The right crushers combined with the right screens, working in a closed circuit, give you good size control.

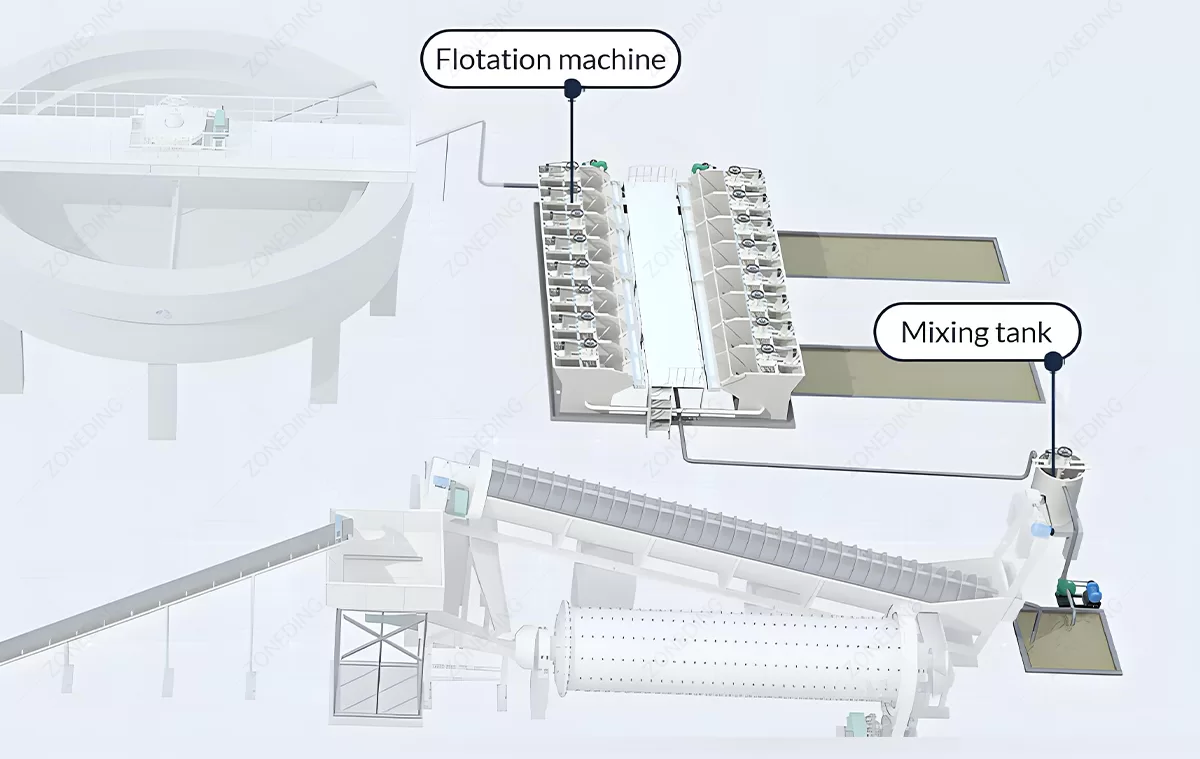

The size of the ore particles after crushing is very important for flotation. Flotation is the main way to separate lead and zinc minerals. It uses chemicals and air bubbles to make the valuable minerals float. The minerals attach to bubbles. They rise to the surface. They are then collected. Waste rock sinks.

Flotation works best when the mineral particles are in a certain size range. If the particles are too big, the lead or zinc mineral might still be stuck inside the rock. It has not been liberated. It cannot float. You lose that mineral. If the particles are too small (fines or slimes), they cause other problems. Fine particles can make the flotation froth difficult to control. They can use more chemicals. They can coat the valuable minerals. This stops them from floating. This also lowers recovery. Fine particles can also make the separation between lead and zinc difficult. You might get lead mixed with your zinc product, or zinc mixed with your lead product.

So, controlling the size of the crushed ore is critical. The crushing plant makes material for the grinding mill (Ball Mill). The grinding mill will break it down even finer, to the very small size needed for flotation. But efficient crushing prepares the feed for the mill. If the crushing output size is controlled well, the mill works better. It uses less energy. It makes the final size for flotation correctly. You control the crushed size using screens (Vibrating Screen). Screens in a closed circuit ensure that rock that is too big goes back to the crusher. Only rock within the desired size range moves forward to the grinding mill. This precise control helps your flotation plant get high recovery of lead and zinc.

Running a lead-zinc ore crushing plant has costs beyond dealing with fines. You buy the machines (Jaw Crusher, Cone Crusher). That is the initial investment. But there are ongoing costs too. These ongoing costs can add up. They affect your profit.

One major cost is wear parts. Crushing rock is hard on machines. Parts that touch the rock wear out. These include the liners inside crushers. They include the mesh panels on screens (Vibrating Screen). The hardness and abrasiveness of your lead-zinc ore affect how quickly these parts wear out. You must buy replacement parts regularly. You must also stop the plant to change these parts. This stopping time is lost production time. Lost production means lost money. Energy use is another big cost. Running crushers, screens, and conveyors uses a lot of electricity. Efficient machines use less power. This lowers your electricity bill. Labor is also a cost. You pay people to operate the machines, do maintenance, and fix problems. If machines break down often, you need more labor for repairs. Designing the plant to be reliable and easy to maintain helps reduce labor costs and downtime. Other costs include things like grease, oil, and water (for dust control). You need to look at all these costs. Choosing reliable, efficient equipment with long-lasting wear parts helps keep your total operating costs low.

Lead-zinc ore is not the same everywhere. The ore from one part of your mine might be different from another part. The hardness can change. The mix of lead, zinc, and waste minerals can change. The amount of clay or moisture can change. Your lead-zinc ore crushing plant must be able to handle these differences. If the plant can adapt, it can stay efficient even when the ore changes.

You can handle these changes in several ways. Crusher settings can often be adjusted. For a Cone Crusher, you can change the gap where the rock comes out. This changes the size of the crushed product. If the ore gets harder, you might need to adjust this. If the mineral liberation size changes, you might need to adjust it. You can also change the screen mesh size (Vibrating Screen). If you need a slightly finer or coarser product for the mill (Ball Mill), changing the screen is how you do it. Sometimes, you might need different types of crushing circuits for different ore zones. A flexible plant design allows for this. Having good control systems also helps. Operators can see how the machines are working. They can make small adjustments based on the ore feed. Regular testing of the ore properties from different areas helps you prepare. You know what changes to expect. You can plan how to adjust the plant. This keeps your plant working at its best performance.

Choosing the right company to build your lead-zinc ore crushing plant is a big decision. You need a partner who understands your specific challenges. Lead-zinc ore is not simple rock. It needs a crushing solution that understands mineral liberation and controlling fines for flotation. A supplier with experience in lead-zinc is key to your success.

Look for a company that has built lead-zinc crushing plants before. Ask about their projects. They should have engineers who are experts in mineral processing, not just general crushing. They should want to study your specific ore. They should ask for samples to test in their lab. Testing helps them understand your ore’s hardness, how it breaks, and how easily the minerals are freed. This testing is very important. Based on the test results and your goals (required production rate, desired final particle size), they should design a customized plant for you. This plant should use the right machines (Jaw Crusher, Cone Crusher, Vibrating Screen). It should have a process design that balances liberation and fines. A good supplier provides the complete service. They design the plant. They manufacture reliable machines. They help with installing the equipment at your site. They train your workers to run the plant. They provide spare parts and support later. This kind of partner helps you get the most value from your lead-zinc ore deposit. They help you build a plant that runs efficiently and profitably for many years.

Q 1: Why are fines bad for lead-zinc flotation?

A: Too many fines make flotation froth hard to control. They increase chemical use. They can lower recovery of lead and zinc. They make separating lead and zinc harder.

Q 2: What crusher type makes fewer fines with brittle lead-zinc ore?

A: A Cone Crusher often makes fewer fines than an Impact Crusher when crushing hard or brittle rock like some lead-zinc ores.

Q 3: How does crushing help the grinding mill?

A: Crushing breaks big rocks into smaller pieces. This prepares the feed for the grinding mill (Ball Mill). The mill uses less energy to grind the rock to the final very fine size needed for flotation.