全站搜索

Search the entire website

Search the entire website

Your cone crusher is the heart of your operation. And its heart is made of steel. Specifically, the Cone Crusher Liner set is where all the work happens. Choosing the right liners, and knowing when and how to change them, is not just maintenance. It is one of the most important things you can do for your profitability. A wrong choice leads to costly downtime. A right choice leads to better product quality and more money in your pocket. This guide will show you what you need to know.

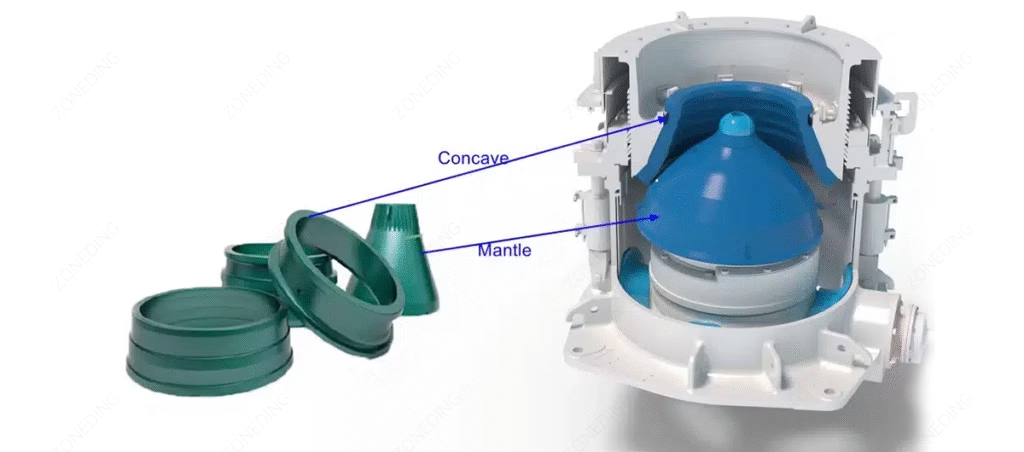

Cone crusher liners are the sacrificial wear parts that protect your crusher. Think of them as the teeth of the machine. They line the inside of the crushing chamber. There are two main parts: the mantle and the concave. The mantle is the moving piece that sits on the crusher head. The concave is the stationary piece that lines the upper frame of the crusher. Rock is crushed in the space between these two liners. They are designed to wear out over time. This protects the much more expensive head and frame components from damage.

These parts are made from special steel. This steel is called manganese steel. It has a unique property. When rock hits it, the surface of the steel gets harder. This is called work-hardening. But underneath this hard surface, the steel remains strong and able to handle big impacts without cracking. Choosing the right grade of manganese steel is critical for getting the longest life from your liners and the best performance from your crusher.

The main difference between crusher liners is the manganese content. While they all look similar, the specific recipe of the steel changes how they perform. The manganese level is the key. You will usually see three main grades: Mn14, Mn18, and Mn22. The “Mn” stands for manganese, and the number is the approximate percentage of manganese in the steel alloy, sometimes with other elements like chromium added.

Choosing the right grade is a balance. It depends entirely on the type of rock you are crushing.

You must match the liner to your specific job. There is no “one-size-fits-all” coHere are the key things to consider:ne crusher liner. Selecting the wrong one will cause poor performance, rapid wear, and even damage to your crusher. The goal is to choose a liner profile and manganese grade that gives you the lowest cost per ton of crushed material.

Here are the key things to consider:

Changing cone crusher liners is a major job that requires safety and precision. Always follow the manufacturer’s specific instructions for your machine. This is a general overview. First, and most importantly, you must follow all safety rules. Lock out and tag out the crusher’s power source. No one should be able to start the machine while you are working on it.

The basic steps are:

The price of a cone crusher liner depends on its size, weight, and material. A liner for a large mining crusher will cost much more than one for a smaller quarry machine. The grade of manganese steel is also a big factor. Higher manganese grades like Mn22 are more expensive than the standard Mn14 because the raw materials cost more.

But you should not choose a liner based on price alone. A cheap, low-quality liner can be the most expensive thing on your site. If it wears out twice as fast, you have to buy two liners instead of one. You also lose money every hour the crusher is stopped for a liner change. A high-quality crusher liner from a reputable manufacturer like ZONEDING might cost more upfront. But it will last longer and produce more tons of material, giving you a much better return on your investment.

You should change your liners just before they are completely worn out. Waiting too long is dangerous. If you wear through a liner, you will start to wear down the head or bowl of the crusher. These are major components that cost a huge amount of money to repair or replace. A new set of liners is cheap compared to a new crusher head.

Look for these signs that it’s time for a change:

Changing your cone crusher liners on time is a proactive way to make more money. It is not just about avoiding damage. It is about keeping your entire operation running at its best. A crusher with fresh, properly shaped liners works better in every way.

The main benefits are:

You can significantly increase your liner life with good operating practices. The liners themselves are tough, but how you run the crusher makes a huge difference. Small changes in your daily operations can add up to hundreds of extra hours of wear life.

Here are the best ways to get more life from your cone crusher wear parts:

We control every step of the process to create superior manganese steel. At ZONEDING, our cone crusher wear parts are not just standard castings. They are the result of advanced metallurgy and strict quality control. The secret to long wear life is in the details of how the steel is made. We use a proprietary recipe with the perfect balance of manganese and chromium. Then, we use a multi-stage heat treatment process.

This process is critical. It creates a very fine, uniform grain structure in the steel. A finer grain structure means the steel is both harder on the surface and tougher throughout. It can withstand the constant grinding and impact inside a crusher without becoming brittle. Many cheaper liners skip these crucial steps. This results in steel that wears out fast or cracks under pressure. Our commitment to metallurgy means you get crusher wear parts that are more reliable and last longer, saving you money in the long run.

We stand behind our products with guarantees that give you peace of mind. We know that crusher downtime is your biggest enemy. That is why we offer more than just parts; we offer a partnership. When you buy cone crusher liners from ZONEDING, you are protected.

Choosing the right impact crusher for your operation is a critical decision that affects your product quality, operational costs, and overall profitability. The two main types, the Horizontal Shaft Impactor (HSI) and the Vertical Shaft Impactor...

View detailsAre you watching your profits wash away with your wastewater? In many sand washing plants, a significant amount of fine sand (75 microns / 200 mesh and smaller) escapes with the overflow water. This isn't just waste; it's lost product and lost re...

View detailsStarting a limestone processing plant is a big project, but it can be very profitable. The process involves taking large rocks from a quarry and turning them into valuable products like construction aggregate or lime. You need a solid plan, the r...

View detailsThe mining screen is what actually makes you money. A screen is the cash register of your entire operation. Its job is to accurately separate your valuable product into sellable sizes. If your screen is inefficient, you are either losin...

View details