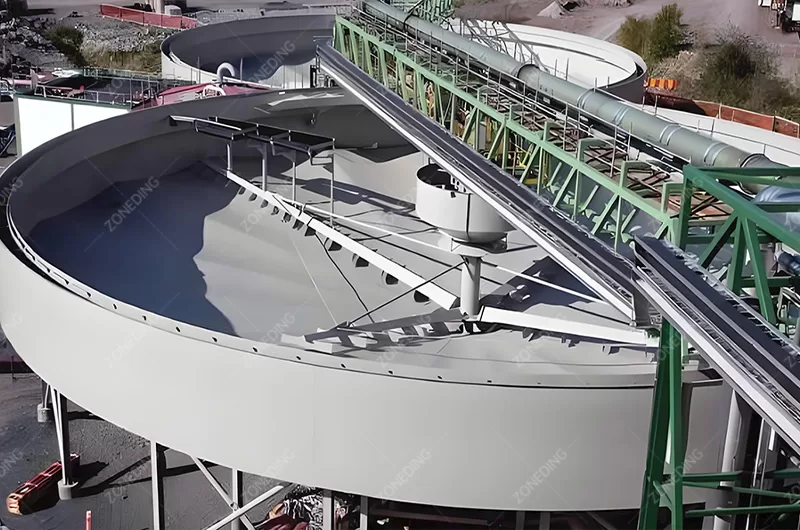

Water is one of the most valuable resources at any mine site. Managing it effectively is key to profitability and environmental responsibility. Mining Thickeners are the workhorses that make this possible. They are large, circular tanks designed for a simple but crucial task: separating solid particles from water in a slurry. By using gravity, these machines recover huge amounts of process water that can be reused, while also thickening the solid waste (tailings) for safer storage. This guide will walk you through everything you need to know about thickeners.

Table of Contents

What Exactly is a Thickener?

A thickener is a large-volume processing tank used for solid-liquid separation. Think of it like a giant, slow-moving settling basin. A mixture of solids and water, called slurry, is fed into the center of the tank. The solid particles takes time to settle to the bottom of the tank due to gravity. At the same time, the clear, separated water rises to the top and overflows into a collection launder. The result is a stream of clean, reusable water and a stream of thickened mud, or underflow, at the bottom.

This process is fundamental in many industries, but it is especially critical in mining. A thickener in mining allows you to handle the massive volumes of slurry generated from processing ore. It is the primary tool for dewatering tailings and concentrating valuable minerals before further processing.

What is the Thickener Used For?

Thickeners are versatile machines with several key jobs on a mine site. Their primary function is always solid-liquid separation, but this applys in a few different ways to improve your entire operation. We design thickener systems to achieve specific goals for our clients.

Here are the main applications:

- Tailings Management: This is the most common use. After extracting valuable minerals, the leftover waste rock and water (tailings) are sent to a thickener. The thickener recovers the water for reuse in the plant and thickens the tailings so they take up less space in the tailings storage facility.

- Water Recovery: Water is expensive to source and treat. Thickeners can recover up to 95% of the process water from a slurry stream. This drastically reduces your need for fresh water, cutting costs and minimizing your environmental footprint.

- Mineral Concentrate Thickening: Before further processing like filtration or leaching, the valuable mineral concentrate is often thickened. This removes excess water, making the downstream processes more efficient and less energy-intensive.

Why is it Critical for Your Mine Site?

Installing the right thickener is not just an operational choice; it’s a strategic business decision. A well-designed slurry thickener directly impacts your bottom line and your license to operate. The financial and environmental benefits are significant. You can save millions of dollars in operational costs over the life of a mine.

- First, water is a major expense. By maximizing water recovery in mining, you reduce the costs associated with pumping, treating, and sourcing fresh water.

- Second, effective tailings management is crucial for safety and compliance. Thickened tailings are more stable and require smaller storage facilities, reducing both risk and capital expenditure.

- Finally, process efficiency improves. By controlling the density of your slurry streams, you ensure that other equipment in your plant, like pumps and filters, operate at their peak performance.

What are Different Types of Thickeners?

Thickeners have evolved over the years to become more efficient. While the principle is the same, the design changes to meet different needs. At ZONEDING, we help you select the perfect type based on your specific slurry characteristics and operational goals.

There are three main types you will encounter:

- Conventional Thickeners: These are the original design. They have a large diameter and a shallow cone at the bottom. These thickeners rely almost entirely on gravity and have a long residence time. They are simple and have a lower initial cost but require a very large footprint.

- High-Rate Thickeners: This is the most common type used today. They are smaller in diameter than conventional thickeners but can process the same amount of slurry. And the Thickeners achieve this by using a flocculant, which makes the solid particles clump together and settle much faster. They are more efficient and require less space.

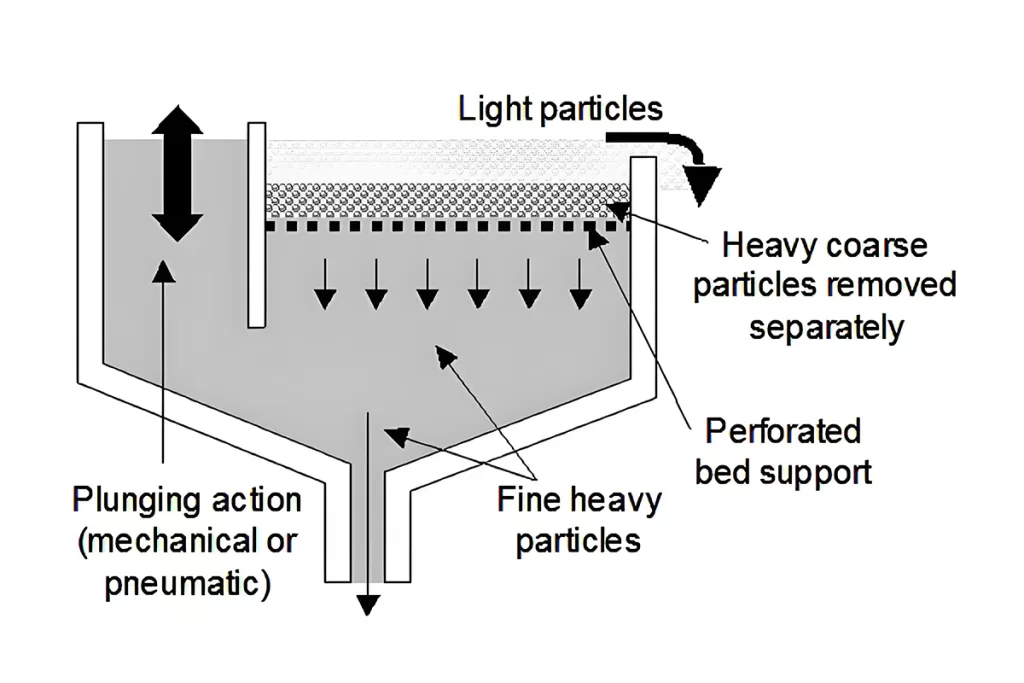

- Paste Thickeners: These are the most advanced type. A Paste Thickener aims to produce a very high-density underflow that is non-segregating, meaning the water doesn’t easily separate from the solids. This “paste” can be pumped and stacked, often eliminating the need for a traditional wet tailings dam. This is the ultimate solution for water conservation and safe tailings storage.

What is the Structure of the Thickeners?

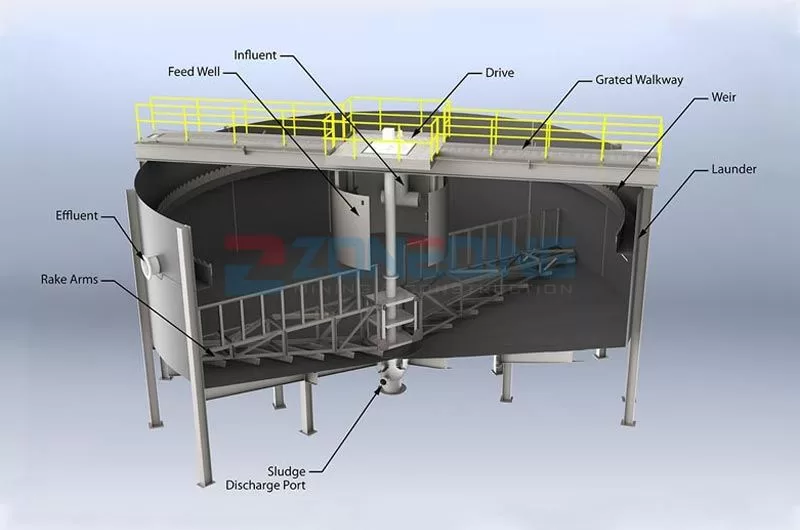

A thickener may look like a simple tank, but it has several key components working together. Understanding these parts helps you appreciate how the machine operates and what to look for during inspections.

Here are the main structural elements:

- Tank: The main body of the thickener, made of steel or concrete, which contains the slurry.

- Feedwell: A central cylinder where the slurry is introduced. It aims to dissipate the energy of the incoming feed and mix it gently with flocculant, promoting particle growth.

- Rake Mechanism: A slow-moving structure at the bottom of the tank. The rake arms and blades gently guide the settled solids towards the central underflow discharge point.

- Drive Unit: A powerful motor and gearbox mounted on a bridge or central column. It provides the torque needed to turn the rake mechanism through the heavy, thickened mud.

- Overflow Launder: A channel around the perimeter at the top of the tank. It collects the clear water that overflows the weir.

- Underflow Cone and Pump: A cone at the bottom center of the tank funnels the thickened solids to a pump, which removes the underflow for disposal or further processing.

How Does the Thickeners Work?

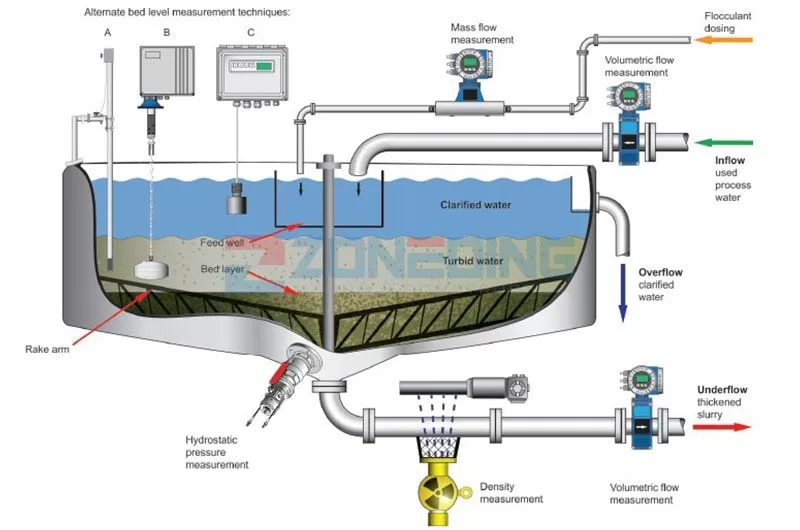

The working process of a modern high-rate thickener is a carefully controlling sequence of events. Each step aims to maximize the speed and efficiency of settling. It is a continuous process that balances inputs and outputs to maintain a steady state.

Here is the step-by-step process:

- Feeding and Mixing: Slurry is pumped into the feedwell at the center of the thickener. At the same time, it will add a diluted flocculant solution. The feedwell designs to mix them gently but thoroughly.

- Flocculation: The flocculant molecules attach to the tiny solid particles, pulling them together to form larger, heavier clumps called “flocs.”

- Settling (Sedimentation): These larger, heavier flocs now sink much faster than the individual particles ever could. They fall through the water and collect at the bottom of the tank, forming a “sludge blanket.”

- Clarification: As the flocs settle, they leave behind clear water. This water rises to the top of the tank.

- Overflow: The clean water spills over the weir at the edge of the tank and is collected in the overflow launder. From here, it is sent to the process water pond for reuse.

- Raking and Compaction: The slowly rotating rakes move through the sludge blanket. This action gently squeezes out more trapped water and pushes the thickened solids towards the central discharge cone.

- Underflow Pumping: The dense, thickened slurry (underflow) is pumped out from the bottom of the cone. Its density is continuously monitored to ensure the thickener is performing correctly.

What is the Price of Thickeners?

The price of a thickener varies dramatically based on its size, type, and features. A small, simple thickener might cost around $100,000. A large, complex paste thickener for a major mining operation could cost over $2 million. It is a significant investment, so it is important to understand what drives the cost.

Several key factors determine the final price:

- Diameter and Height: Larger tanks require more steel and more complex engineering, so they cost more.

- Type: A high-rate thickener is more expensive than a conventional one of the same size, and a paste thickener is the most expensive due to its heavy-duty drive and steep cone design.

- Drive Unit Torque: The thicker the underflow you need, the more powerful (and expensive) the drive unit must be to turn the rakes.

- Materials of Construction: If your slurry is corrosive, you will need special materials like stainless steel or corrosion-resistant coatings, which adds to the cost.

- Automation and Instrumentation: Advanced sensors for measuring density, turbidity, and bed level add cost but improve performance and reduce operator workload.

What Parameters of Thickeners you Should Notice?

When you are evaluating a thickener, you need to look at specific technical parameters. These numbers define the machine’s capabilities and suitability for your project. Our engineers at ZONEDING work with you to define these parameters based on your unique needs.

Pay close attention to these specifications:

- Processing Capacity: Measured in tons of solids per hour (tph) or cubic meters of slurry per hour (m³/h). This must match your plant’s output.

- Thickener Diameter: The primary sizing factor. A larger diameter provides more settling area.

- Underflow Density: The target percentage of solids in the underflow. This is a key performance indicator.

- Overflow Clarity: The quality of the recovered water, often measured in parts per million (PPM) of suspended solids.

- Drive Unit Torque Rating: Measured in kilonewton-meters (kNm). It must be high enough to handle the thickest possible underflow without stalling.

- Rake Speed: The rotational speed of the rakes, usually very slow (measured in revolutions per hour).

How to Choose the Suitable Thickeners for Your Project?

Choosing the right thickener is a critical engineering decision. An undersized thickener will create a bottleneck in your plant, while an oversized one is a waste of capital. A systematic approach will help to ensure you get the perfect fit.

Follow these steps for a successful selection process:

- Characterize Your Slurry: First, you must understand your material. We need to know the particle size distribution, solids specific gravity, and the settling characteristics of your slurry.

- Define Your Performance Goals: What do you need to achieve? Specify your target underflow density and required overflow water clarity. These goals will determine the type and size of the thickener.

- Conduct Settling Tests: This is the most important step. Lab tests using your slurry sample determine the required settling area (unit area) and the optimal flocculant dosage. At ZONEDING, we perform these tests for our clients to guarantee our design.

- Calculate the Size: Using the test data and your required throughput, our engineers calculate the necessary diameter and height of the thickener.

- Select the Type and Features: Based on the goals and test results, we will recommend the best type of thickener (high-rate or paste) and features like an automatic rake-lifting mechanism.

Operation Tips for Thickeners

Proper operation is key to getting consistent performance from your thickener. It is a large, dynamic system that requires careful monitoring.

Prepare:

- Ensure all instruments (density meters, pressure sensors) are calibrated.

- Check that the flocculant system is working and has enough reagent.

- Verify that the underflow pump is ready and the pipeline is clear.

Operating:

- Start the feed and the underflow pump at the same time to avoid sanding the cone.

- Gradually increase the feed rate to the target.

- Constantly monitor the underflow density, overflow clarity, and the sludge blanket level. Adjust flocculant dose and underflow pump speed to maintain your targets.

Inspecting:

- Listen for any unusual noises from the drive unit.

- Check for leaks in the tank or piping.

- Observe the overflow water. If it becomes cloudy, your process needs adjustment.

Operation Procedures:

- Develop standard operating procedures (SOPs) for startup, shutdown, and handling upset conditions.

- Train operators to understand the relationship between flocculant dose, underflow pumping rate, and thickener performance.

Maintenance Tips for Thickeners

A thickener is a robust machine with long-life, but it requires regular maintenance to prevent costly downtime. A simple preventative maintenance schedule can save you from major repairs.

- Daily: Check the oil level and temperature of the drive unit gearbox. Walk around the thickener to look for leaks or structural issues.

- Weekly: Lubricate all grease points on the drive unit and rake lifting mechanism. Clean and calibrate key sensors.

- Monthly: Take an oil sample from the gearbox for analysis. This can predict potential failures before they happen. Inspect the rake blades for wear, especially if your slurry is abrasive.

- Annually: Plan a shutdown for a full inspection. Enter the tank (following all safety procedures) to check the condition of the rakes, cone scrapers, and the tank lining.

FAQ

- What is Flocculant and is it Always Necessary for Settling?

- A flocculant is a special polymer that acts like a magnet for fine solid particles in the slurry. It neutralizes their surface charges, allowing them to stick together and form large clumps (flocs) that settle very quickly. For most mining thickeners dealing with fine particles, flocculant is absolutely necessary to achieve high throughput in a reasonably sized tank.

- How Does Underflow Density Directly Impact Your Profitability?

- Higher underflow density means more water has been removed from the solids. This impacts your profitability in two ways. First, every liter of water recovered from the underflow is a liter you don’t have to pump from a fresh source, saving energy and water costs. Second, denser tailings require a smaller, cheaper tailings storage facility.

- How Can You Maximize Water Recovery and Reduce Environmental Impact?

- Maximizing water recovery is achieved by producing the highest possible underflow density. Using a Paste Thickener is the most effective method. It can produce an underflow with over 70% solids, recovering the maximum amount of water. This dramatically reduces your mine’s water footprint and creates safer, stackable tailings with a smaller environmental impact.

- How Does ZONEDING Test Your Slurry to Guarantee Peak Thickener Performance?

- We believe in engineering from data, not guesswork. You send our lab a representative sample of your slurry. We perform a series of tests to determine its settling rate, the optimal type and dose of flocculant, and the final density that can be achieved. This data allows us to precisely size and design a thickener that is guaranteed to meet your performance targets from day one.